Key Features

FEEDER BREAKER HFB

TECHNICAL DATA

FEEDER BREAKER HFB

| Type | Average feed size [mm] | Throughput rate [t/h] | Drive capacity [kW] |

| HFB 0714 | 500 x 1.300 x X | 250 - 500 | 90 - 160 |

| HFB 1014 | 800 x 1.300 x X | 500 - 1.000 | 110 - 200 |

| HFB 1111 | 1.200 x 1.100 x X | 300 - 500 | 90 - 160 |

| HFB 1414 | 1.500 x 1.400 x X | 700 - 1.100 | 132 - 320 |

| Values are variable and can be aligned to the particular requirements. | |||

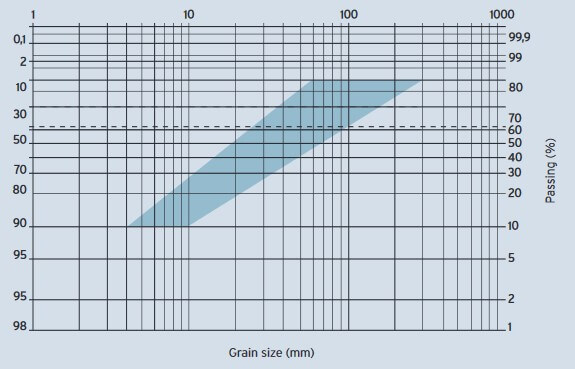

Granulation Curves

PRODUCT DESCRIPTION

The HAZEMAG Feeder Breaker HFB is a complete horizontal roll crusher plant, which operates on the field-proven principle of crushing in the horizontal material flow.

The Feeder Breaker consists primarily of two machine components: the crushing roll and the chain conveyor. The arrangement of the crushing roll above the chain conveyor allows the chain conveyor to be employed as both the feed conveyor and the discharge conveyor.

The design and arrangement of the picks on the crushing roll, as well as the scrapers in the conveyor, are main factors that determine the product size but, with the height-adjustable crushing roll and adjustment of the chain conveyor’s conveying speed, via a frequency converter, the granulation size can be adjusted to suit customer requirements.

Typical Applications

- Underground coal and salt mining

- Open pit gypsum, chalk and coal mining

- Stockyards and transshipment sites; especially for slag, petroleum coke, and others

Additional Equipment

- Feed hopper

- Pre-screening with integrated HAZEMAG Roller Screen HRS

- Crushing feed material, directly at the face, to suitable size for belt conveyor transport

- At-Grade material feeding

- Installation without foundation works

- Highly mobile

- Variable length of chain conveyor

- Arrangement of picks to suit application

- Steel substructure / skids

- Sliding skid, hydraulically adjustable in height

- Free-rolling crawler track

- Powered crawler track

The exclusive and unique computer-controlled hydraulic adjustment system for the impact aprons (and grinding path) allows for quick gap adjustments, optimum control over product size, smoother crusher operation, tramp iron protection, reduced downtime and reduced operating costs. With our technically-advanced HAZtronic system, impactor performance can be optimised with automated procedures and pre-programmed apron settings to further enhance product quality and consistency.