High quality for cement and aggregates

The global supplier for cement and aggregates processing

HAZEMAG’s process knowledge and unique technologies enable safe, reliable, continuous production solutions for the global Cement & Aggregates industry.

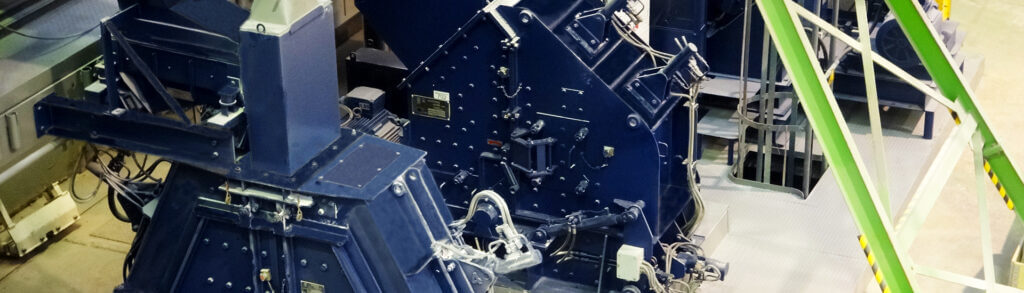

The success of cement and aggregate producers depends on the reliability, safety and uninterrupted production of their operations. As a supplier of machines and systems for cement, aggregates and more, HAZEMAG ranks among the world’s pioneers in proven raw materials crushing and processing solutions. The HAZEMAG name has been synonymous with engineering excellence since its foundation in 1946 with the invention of the world’s first impact crusher for cements and aggregates. Today, HAZEMAG has an installed base exceeding 75,000 machines worldwide, and is uniquely positioned to provide its global cement and aggregate customers with the process knowledge, technology and associated service they require to optimise their operations.

For over a century, HAZEMAG’s expertise has perfected the development of innovative, state-of-the-art products and enabled our customers to achieve their project goals. The company’s product development, with wide-ranging application success, is acknowledged throughout the aggregate and cement industries. The construction industry is particularly reliant on plentiful supplies of a quality-controlled concrete and well-graded aggregate, and HAZEMAG equipment ensures a high-quality product.

With low emissions, HAZEMAG’s comprehensive range of modern equipment is environmentally-friendly, designed to function efficiently, with ease of operation and safety in mind, and to deliver the optimum solution: whether it’s a single machine or a complete processing plant.

The cement industry plays an essential role in today’s environment, and cement has made a major contribution to people’s quality of life around the world. The use of cement in concrete has an impact on virtually all aspects of our daily lives, including: residential and commercial construction; roads, bridges, tunnels and airports; dams and water and sewage treatment plants. HAZEMAG’s concrete process know-how, coupled with high-quality reliable machinery and service, plays an important part in the crushing and processing of raw materials that ultimately result in essential cementitious products.

Cement production requires a blend of limestone and clay combined with other materials such as slag sand, quartz sand, materials containing iron oxide, gypsum, schist or similar additives. Portland cement clinker is the sintered component in cement which is responsible for it curing with the addition of water. As complex and customised as the process of making cement, are the systems and technologies that are required, but one common factor always remains in place: The raw materials require crushing.

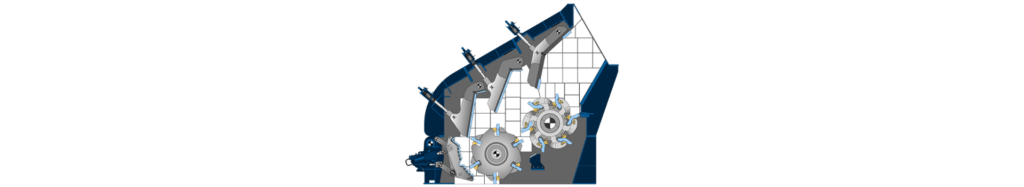

In a vertical roller mill or ball mill, the pre-crushed materials are further ground. The optimum feed grain size for each one of these mills is different; each normally requiring different pre-crushing systems for the production of the correct feed granulation. If not approached correctly, such mistakes can lead to a significant rise in the energy costs associated with the comminution or material pulverising process.

An important factor in the production of cement is the lime saturation factor (LSF). LSF is determined by the ratio of lime, to silica, alumina and iron oxide, and must be kept at a constant ratio, within narrow limits. Correct selection of the primary crushing plant or system is the first stage in influencing the LSF.

Control over components such as the limestone and clay (or marl) is indispensable. In many cases, depending on the material characteristics and percentages of each, the limestone and clay can be processed together in a single crusher. Under these conditions, a certain level of homogenisation is already taking place, and selection of the correct equipment is of vital importance to further optimise the final and product operating costs.

Selection of the complete system is more important than any single item of machinery or an individual component. For example, although a compressive type crusher operates with less energy and wear, due to its lower reduction ratio and larger product size, a secondary crushing system will be required to achieve the desired product size.

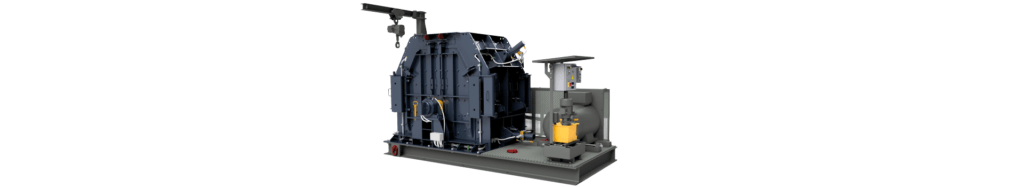

On the other hand, with the right machine for the raw material being processed, a primary impactor can offer major advantages by achieving the desired reduction ratio for the required end product. The key is to find the correct and optimum solution.

At HAZEMAG you’ll always find what you’re looking for – industry expertise, proven capability, a range of equipment solutions and technologies… and a reliable partner.

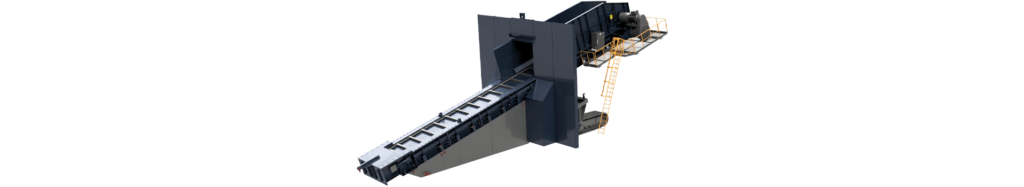

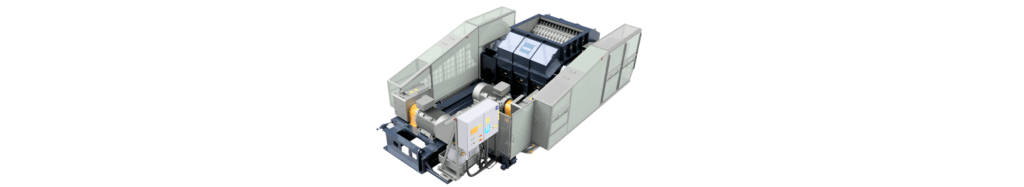

A primary pre-crushing plant normally comprises:

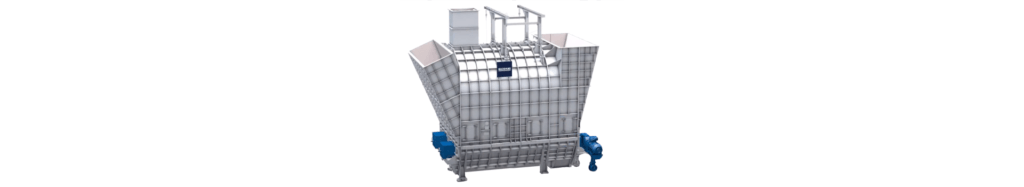

■ Feed Hopper

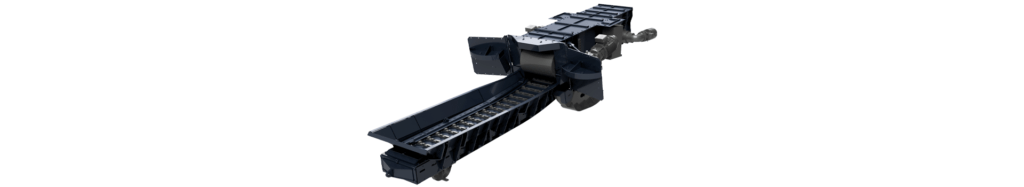

■ Hopper Discharge Unit

■ Pre-screening Stage

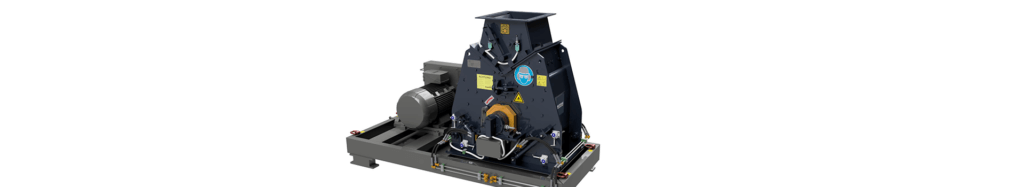

■ Primary Crusher

■ Crusher Discharge Unit

Depending on the characteristics and size of the feed material, these components must be manufactured to a heavy-duty design and robustly engineered to ensure reliable, trouble-free operation and long service life, and machines must be able to deal with the possible entry of foreign metallic materials such as loader teeth, etc.

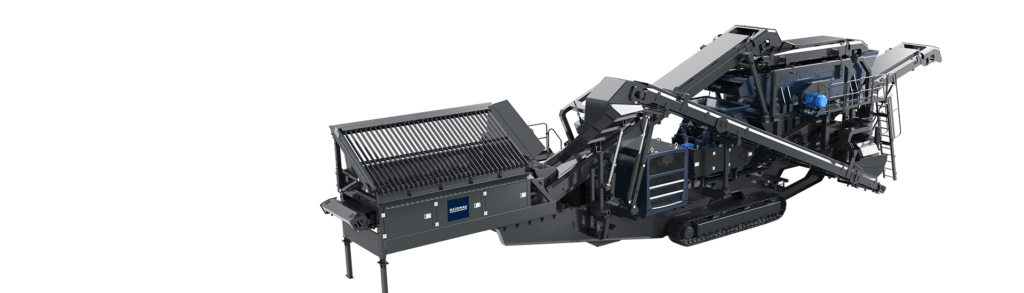

The characteristics of the raw material; moisture content, inclusion of clays, compressive strengths and chemical make-up highly influence not only the selection of aggregates, but also the type of primary crusher that can be utilised. Depending on the raw material resources, and transport considerations, the use of mobile primary crushing plant can be considered.

Aggregates such as limestone, granite and gravel are essential commodities in today’s world, and make a major contribution to our lives and our environment. These natural resources are vitally important for residential and commercial construction and the development of our transport infrastructure; as well as being employed in the production of fertilisers, toothpaste, and even cosmetics. For the building industry, HAZEMAG machinery is used in the production of high-quality gravels and sand that are valuable raw materials for a multitude of industrial projects.

As varied and different as the geological make-up of these natural resource, are the systems and technology that are selected in order to meet a vast range of specifications and consumer demands. However, a common factor always remains in place; the basic material must be crushed.

In simple terms, crushing can be defined as the process of changing the size and quality characteristics of the raw stone by the use of an external source, such as a crusher. More specifically, the crushing process must meet a range of crucial specification targets, such as:

■ Changing the size of the raw material in its natural state in order to meet a range of construction specifications commonly associated with concrete, road base and asphalt chips, and even finer products utilised in paints, fertilisers and pharmaceuticals.

■ Changing the shape of the raw material in order to meet those construction specifications that require, for example, a more cube-shaped product.

■ Increasing the quality of the raw material, known as beneficiation or selective crushing, which enhances the raw material by the elimination of softer, unwanted materials or inclusions.

■ ´Upgrading´ the material; increasing its quality by eliminating natural cleavages or internal weaknesses.

In order to achieve these and other targets, aggregates processing plants typically comprise of a combination of crushing and screening in multiple stages: primary, secondary and at times tertiary processing.

Systems for processing aggregates can be complex and the cost often represents a major investment for a business. The decision-making process of selecting the correct equipment is highly important, but the success of any project is not dependent on individual pieces of equipment. The ability to produce products of the highest possible quality, at least possible cost, comes from the quality of the overall system design; a design that delivers proven equipment and technology, with safe, efficient and flexible operation, has minimal maintenance requirements, and produces minimum volumes of waste.

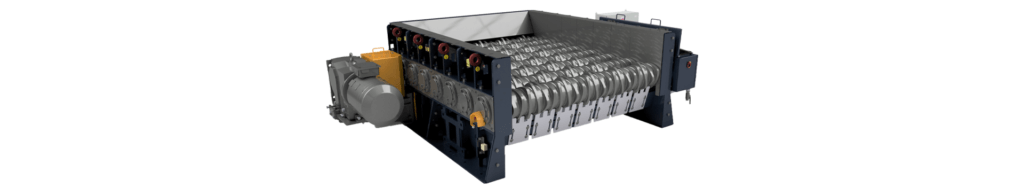

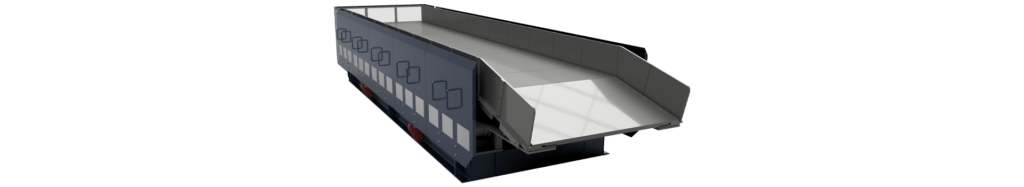

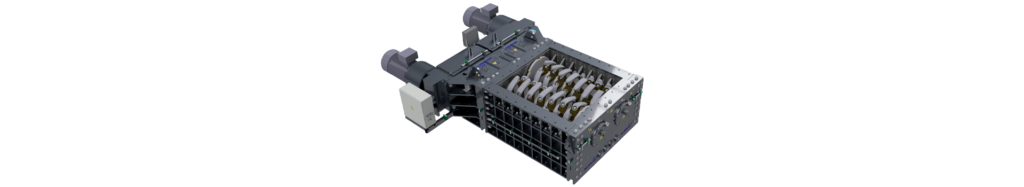

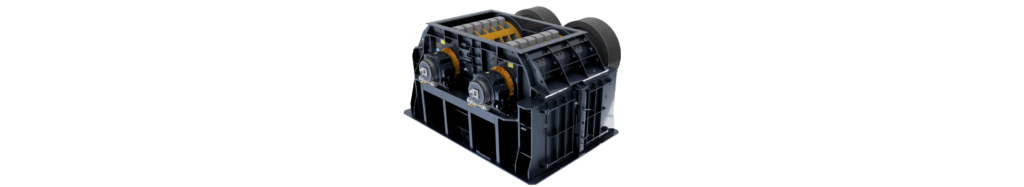

CEMENT & AGGREGATES PRODUCTS

- All

- dynarox

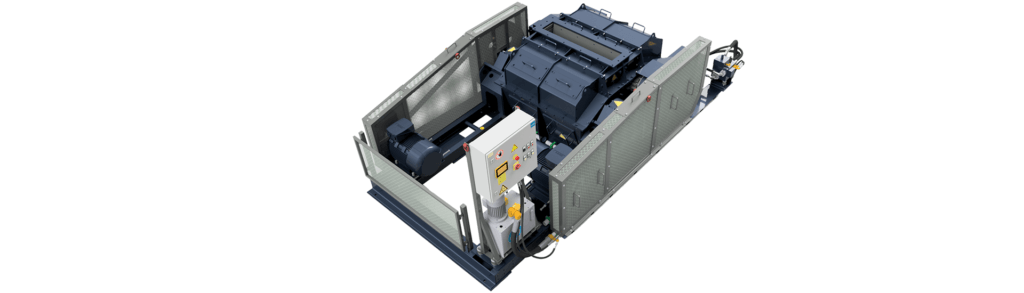

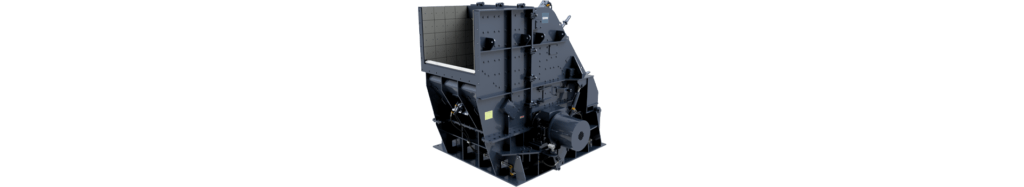

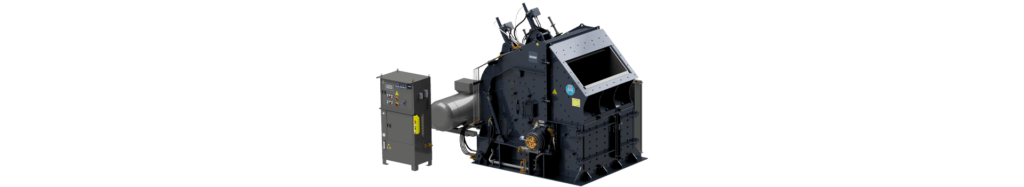

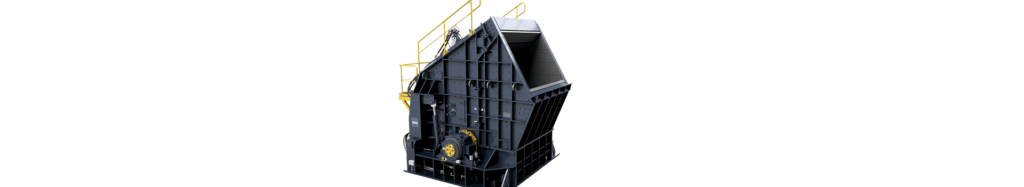

- Impactors

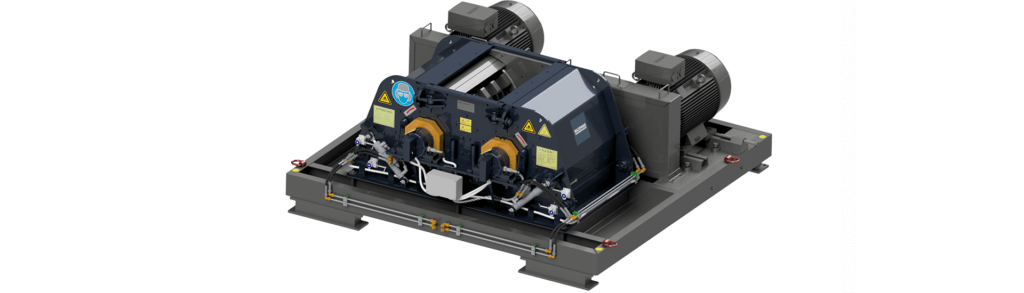

- Roll Crushers

- Sizers

- Horizontal Crushers

- Hammer Mills

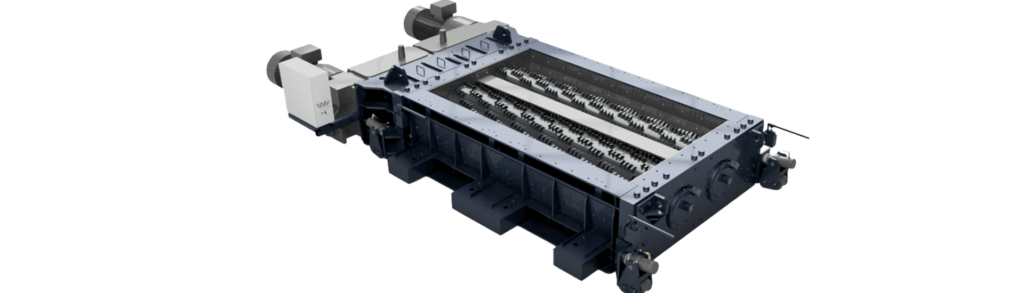

- Roller Screens

- Feeders

- Hammer Crushers

- Dryers

- Automation

- Material Testing