Key Features

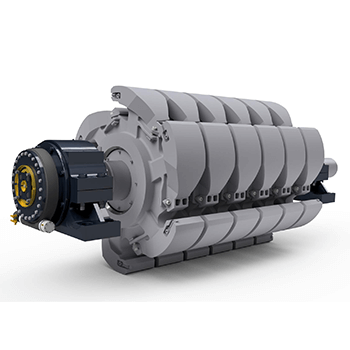

COMPOUND CRUSHER HPC

TECHNICAL DATA

COMPOUND CRUSHER HPC

| Model | Rotor Diameter mm | Power Requirements kw | Inlet Height x Width mm | Maximum Feed Size m3 / mm | Rotor Diameter x Width mm | Weight kg | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| HPC-1414 | 230 | 250/315 | 950 x 1.420 | 0.5 (1.000) | 1.340 x 1.340 | 28.000 | ||||||

| HPC-1615 | 400 | 400/500 | 1.400 x 1.520 | 1.0 (1.200) | 1.640 x 1.500 | 62.000 | ||||||

| HPC-1618 | 470 | 500/560 | 1.400 x 1.820 | 1.2 (1.300) | 1.640 x 1.800 | 70.500 | ||||||

| HPC-1622 | 550 | 560/710 | 1.400 x 2.270 | 1.4 (1.500) | 1.640 x 2.250 | 92.000 | ||||||

| HPC-1822 | 850 | 900/1.000 | 1.500 x 2.270 | 2.0 (1.500) | 1.800 x 2.250 | 101.000 | ||||||

| HPC-2022 | 1.150 | 1.200/1.400 | 1.770 x 2.270 | 2.2 (1.500) | 2.000 x 2.250 | 131.000 | ||||||

| HPC-2025 | 1.325 | 1.300/1.600 | 1.770 x 2.520 | 2.3 (1.600) | 2.000 x 2.500 | 160.000 | ||||||

| HPC-2030 | 1.650 | 1.650/2.000 | 1.770 x 3.020 | 2.4 (1.700) | 2.000 x 3.000 | 180.000 | ||||||

| Note: Performance details relate to medium-hard limestone | ||||||||||||

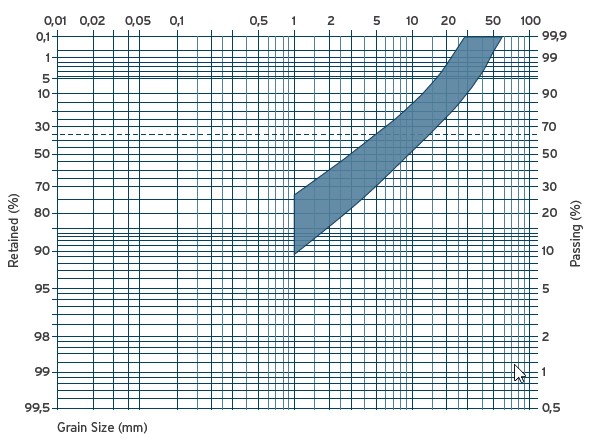

Granulation Curves

PRODUCT DESCRIPTION

The HAZEMAG HPC is a double-rotor Primary Crusher used in the cement industry to generate suitable feed material, for further processing in ball mills, during the production of raw meal for cement manufacture.

The HAZEMAG HPC offers two-stage crushing, within a single housing, by two co-rotating rotors operating in tandem. The first rotor crushes feed rock up to 3m³ in volume, and the second rotor, which runs at a higher speed, reduces the feed material to product size. The HPC crusher has 2 or 3 impact aprons and a grinding path, with settings controlled either by spindles and/or hydraulics; allowing optimum control of the end product granulometry. The grinding path restricts the amount of oversize.

The rotor is the key component in the crushing process. Its body, together with shaft and bearings, forms the “heart” of the impact crusher.

GSK-ROTOR

This patented rotor is HAZEMAG’s own design and is a cast and welded steel construction, with individually cast rotor discs welded to the rotor body, to accommodate the proprietary blow bars as primary crushing implements. The blow bars are locked in position in the holders by means of wedges, which can be easily removed for blow bar replacement.

To protect the rotor body and blow bars, the impact aprons retract under excessive load. Two versions are available:

Mechanical system

The impact apron is held in position by means of a thrust device with pressure springs. Spindle adjustment is assisted by auxiliary hydraulics.

Hydraulic system

The impact aprons are retained in position by hydraulic cylinders; allowing adjustment and locking at the touch of a button. The instant a pre-set limiting value is overstepped in the crushing chamber, the impact apron retracts in a controlled manner. As soon as the load value returns to normal, the impact apron resumes its pre-set position, and operation continues without interruption.

In the field of primary crushing in the cement industry, the grinding path plays a crucial role in the process to reduce oversize. The grinding path in the HAZEMAG HPC series of crushers employs a technically proven system of hydraulics and mechanics to effect retraction of the grinding path in the event of an overload. This patented solution increases operational safety and availability, since potential damage caused by tramp material, and the resulting downtimes, are significantly reduced.

In the cement industry the grinding path is the critical component for reducing oversize in the process of primary crushing. The grinding path of the HAZEMAG HPI-H series has been significantly improved, with a technically-advanced system of hydraulics and mechanics allowing retraction in the event of an overload. This patented solution increases operational safety and production capacity, and the potential for damage and excessive downtime resulting from foreign objects is greatly reduced.

The exclusive and unique computer-controlled hydraulic adjustment system for the impact aprons (and grinding path) allows for quick gap adjustments, optimum control over product size, smoother crusher operation, tramp iron protection, reduced downtime and reduced operating costs. In our technically advanced HAZtronic system, impactor performance can be optimised with pre-programmed apron settings to further enhance product quality and consistency.

- AP-CM

- AP-CMH