CARACTÉRISTIQUES PRINCIPALES

UNIROTOR VARIO HUV

DONNÉES TECHNIQUES

UNIROTOR VARIO | HUV

| Type | Débit* [mt/h] | Longueur maximale du bord [mm] | Hauteur x largeur intérieure [mm] | Puissance installée* [kW] |

| HUV 1013 | 110 | 120 | tbd | 315 |

| HUV 1020 | 180 | 120 | 510 x 1,950 | 450 |

| HUV 1412 | 115 | 220 | 376 x 1,240 | 315 |

| HUV 1417 | 210 | 220 | 580 x 1,825 | 525 |

| HUV 1622 | 360 | 280 | 770 x 2,385 | 900 |

| HUV 1626 | 390 | 280 | - | 1,000 |

| HUV 1630 | 450 | 280 | - | 1,200 |

| HUV 1634 | 510 | 280 | - | 1,300 |

| * calcaire de dureté moyenne 95%< 6mm - les valeurs sont variables et peuvent être alignées sur les exigences particulières. | ||||

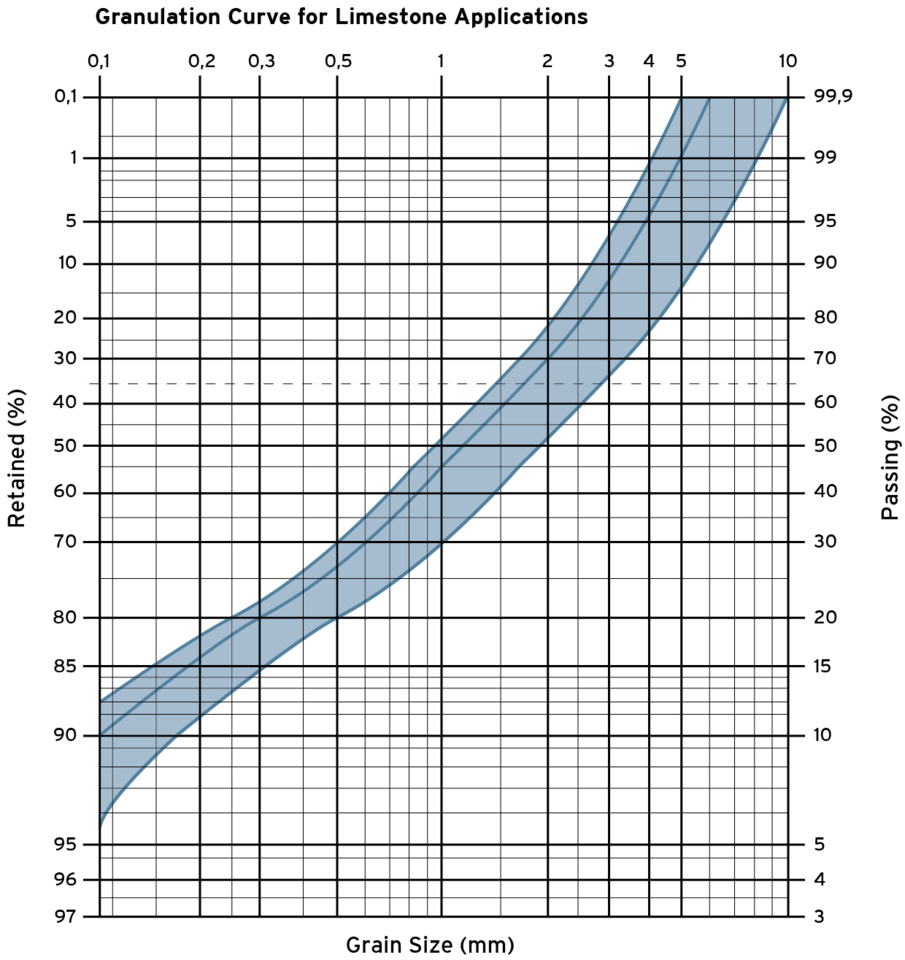

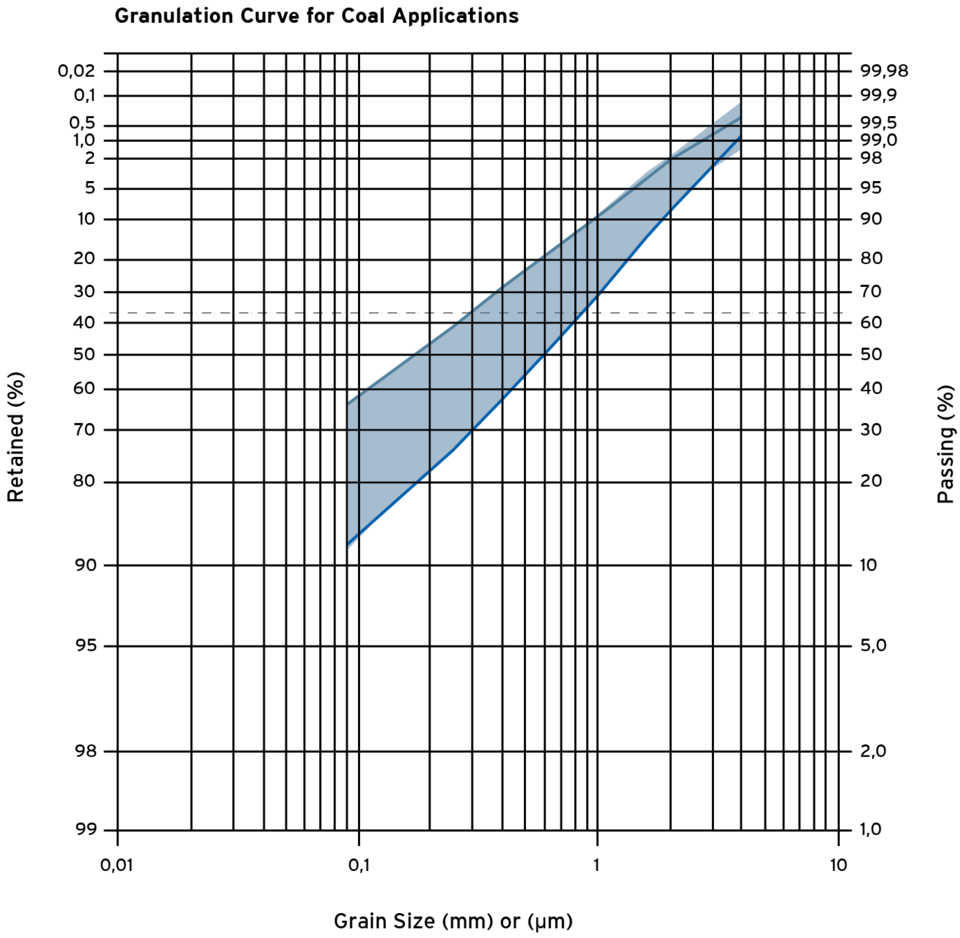

COURBES GRANULOMETRIQUES

DESCRIPTION DU PRODUIT

Les broyeurs à marteaux HUV de HAZEMAG sont principalement utilisés dans les secteurs des matières premières, ainsi que dans l’industrie sidérurgique, pour le broyage secondaire et tertiaire de divers matériaux. Ils sont souvent utilisés pour le broyage fin de matériaux mi-durs à tendres tels que l’anhydrite, la chaux vive, le lignite, le charbon, le schiste bitumineux, la dolomie, la craie, le gypse, le verre, l’argile, le calcaire, etc.

Le matériau d’alimentation, qui est acheminé vers la chambre de traitement, est broyé par impact ainsi que par attrition. L’impact se produit à l’entrée, mais le matériau broyé est principalement fragmenté par des coups par l’effet de rétraction du rotor dans la partie inférieure de la chambre de broyage qui se rétrécit. Le matériau reste dans l’espace de travail jusqu’à ce qu’il soit déchargé par les interstices de la grille ou la section d’ouverture. Le parcours de broyage limite la quantité de surépaisseur et favorise la génération d’un produit cubique et sans contrainte.

Les broyeurs à marteaux HUV sont conçus de telle manière qu’ils fonctionner à des vitesses de rotor continues ou variables. Des trappes d’inspection et des boîtiers à charnière sont prévus pour faciliter l’entretien et permettre l’accès à toutes les pièces d’usure et aux voies de broyage.

Le carter du broyeur, qui ne subit aucune contrainte, est protégé contre l’usure par des plaques latérales boulonnées en matériau résistant à l’usure et, étant monté sur un châssisantivibratoire, il réduit considérablement les charges dynamiques. Les deux côtés du carter du broyeur peuvent être ouverts ou fermés hydrauliquement.

Un composant essentiel des broyeurs à marteaux HAZEMAG est le rotor à disques, sur lequel sont montés les marteaux mobiles. Le rotor robuste est de type disque en acier, avec des marteaux à mouvement libre (360°) montés entre les disques. Il est monté sur un arbre et équipé de roulements à rouleaux auto-alignants. Le rotor peut également fonctionner dans les deux sens, ce qui optimise l’utilisation des marteaux et élimine la nécessité de les tourner manuellement. Les marteaux sont fabriqués en fonte composite, facile à remplacer, et la conception finement équilibrée des marteaux opposés assure un fonctionnement équilibré. La suspension flexible des marteaux sur le rotor garantit que le broyeur à marteaux HUV est suffisamment robuste pour résister à l’intrusion de particules étrangères extrêmement dures.

Rotor réversible et non-réversible

Sur la version réversible, les marteaux peuvent être utilisés de manière optimale en inversant le sens de l’entraînement sans avoir à inverser les têtes elles-mêmes. Sur le modèle HUV non réversible, une seule trajectoire de broyage peut être utilisée. À la place du chemin de broyage, une plaque incurvée est installée pour protéger le carter.

Le HUV peut être entraîné à une vitesse constante ou variable.

Tous les broyeurs à marteaux HAZEMAG HUV sont équipés d’un dispositif de rotation du rotor – permettant de déplacer et de verrouiller le rotor dans la position appropriée pour un remplacement sûr et facile des marteaux.

Le dispositif de rotation du rotor comprend un engrenage à vis sans fin avec un entraînement et un frein hydrauliques.

Pour les produits fins, un panier à grille optionnel peut être installé, avec des barres de grille intégrées au panier à grille. Cet ensemble confère aux barres de grille intégrées la stabilité mécanique nécessaire et fixe en même temps la largeur des barres de grille requise pour obtenir une taille de produit spécifique. Le mouvement d’entrée et de sortie du support du panier à grille est contrôlé hydrauliquement.

Les chemins de broyage peuvent être fournis avec un système de chauffage installé. Les parois d’impact chauffées peuvent améliorer le flux de matière lors du traitement de matières premières contenant une certaine quantité d’humidité, qui ont tendance à former des gâteaux. L’huile conductrice de chaleur est pompée dans un circuit de tuyauterie installé derrière les voies de broyage, et la face arrière de la tuyauterie chauffée est isolée de manière appropriée.