Our Roller Screens

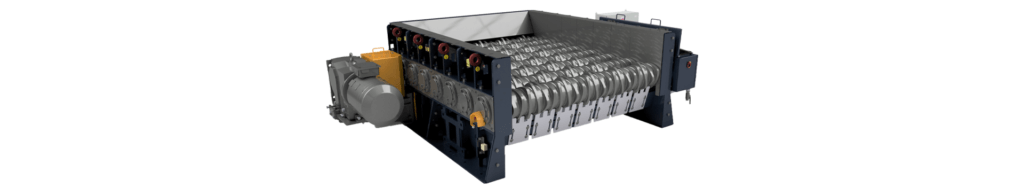

Roller screens belong to the group of classifying machines. The screen surface of the roller screen is formed by a series of shafts on which discs are attached.

The roller elements, which are arranged one after the other horizontally or slightly inclined in the direction of transport, are driven by chains. The partition openings corresponding to the arrangement of the differently shaped discs are square or rectangular.

Prescreening is an excellent way to remove lower quality, unwanted contaminations from the raw material stream. In doing so, benefits such as increased product quality, reduced crusher wear and reduced energy costs are fully realized. Prescreening can also lead to the reduction and cost savings regarding the size of the primary crusher, as the volume of material that needs crushed is reduced.

The prescreening stage should workload independent, thus enhancing its success and high efficiency in removing the finer materials, while allowing it to successfully deal with adverse conditions, such as sticky components. When considering the prescreened material, in some cases blending it back together with the crushed material may be desired. However, under this condition some level of caution should be taken to ensure that the screening size (opening) is not too large, potentially allowing an excessive amount of oversized slabs to pass.