Key Features

RAPID DRYER HRD

TECHNICAL DATA

RAPID DRYER HRD

| Type | Agitator Shaft Dimensions [mm] | max. Water Vaporisation* [kg/h] |

| HRD 0630 | 590 x 3.000 | 670 |

| HRD 0637 | 590 x 3.740 | 800 |

| HRD 0837 | 780 x 3.740 | 1.400 |

| HRD 0940 | 900 x 4.040 | 2.800 |

| HRD 0946 | 900 x 4.640 | 3.800 |

| HRD 1051 | 1.050 x 5.060 | 5.100 |

| HRD 1061 | 1.050 x 6.080 | 6.600 |

| HRD 1261 | 1.240 x 6.080 | 10.000/13.5000 |

| HRD 1861 | 1.800 x 6.080 | 17.000/21.000 |

| HRD 2170 | 2.100 x 7.040 | 27.000 |

| * depending on feed material size distribution and density | ||

PRODUCT DESCRIPTION

The HAZEMAG HRD Rapid Dryer is a highly efficient, field-proven dryer which combines the advantages of short-time drying and uniflow drying. With the material to be dried turned mechanically, with agitator paddles, and a simultaneous flow of hot gas through the material, gentle thermal drying is possible in a short time.

Thermal drying (water vaporisation) in the HRD Rapid Dryer is suitable for use in diverse applications across a wide spectrum of materials including: Clay and loam, limestone chippings, pozzolana, iron ore, aluminium hydroxide, gypsum (natural, chemical, flue gas), fluorspar and bauxite.

These materials mostly comprise moist filter cake (25-30% moisture) or pasty products, and must be dried to specific moisture values which can be achieved by appropriate design of the rapid dryer.

Hot gas and feed material are passed through the rapid dryer in parallel flow. The feed material is mechanical agitated by flow blades, mounted on two shafts, to break-up and disperse the material. The HAZEMAG Rapid Dryer HRD achieves thermally-mild drying, in a short space of time – but without causing material damage associated with overheating.

Drying gases are generally provided by an oil or natural gas-fuelled hot gas generator, and the temperature of the hot flue gas is typically between 500°C and 800°C.

With Uniflow drying, the material to be dried and the hot drying gas pass through the rapid dryer in the same direction. This offers the advantage that high gas temperatures can be used for drying in the entry zone without damaging the material. When the hot gases meet the wet material, intensive water evaporation results, along with simultaneous decrease in temperature of the drying gas.

This method of rapid drying is especially advantageous for drying moist, plastic clay and difficult-to-dry filter cake that has previously been mechanically dewatered on belt filters, filter presses, drum filters or centrifuges. Typical examples of such materials include FGD gypsum, chemical gypsum, chromium hydroxide, etc. The material to be dried is de-agglomerated and rotated in the dryer; significantly increasing the surface area of the material, which enables intensive material and heat exchange. Thanks to its compact design of HAZEMAG’s Rapid Dryer, only a relatively small space is required for installation and operation.

The HAZEMAG Rapid Dryer HRD consists of a frame, lower housing section, upper housing section, hot gas nozzles, exhaust gas nozzles, and drive units.

The two rotating agitator shafts are situated in the lower housing. The dryer is partially protected against wear with a lining to the interior compartment, and shaft bearings at the feeder side are cooled with water, if required. The agitator shafts are fitted with throw arms, to which throw blades are bolted, and the internal height of the compartment walls is adjustable to control the length of time feed material is retained.

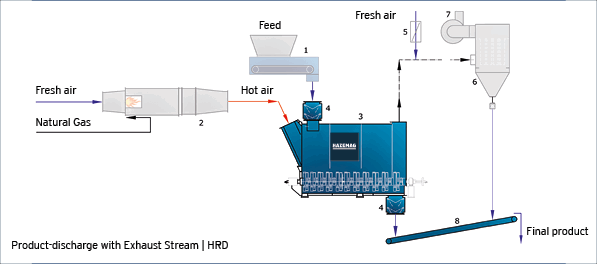

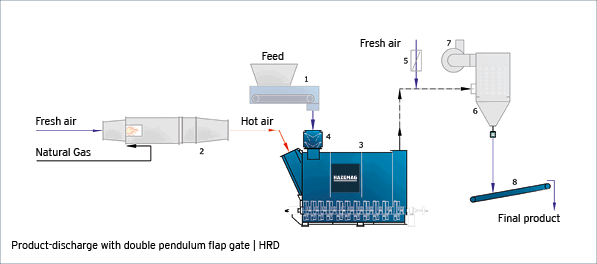

- Feeding equipment

- Hot gas generator

- Rapid Dryer HRD

- Double pendulum flap gate HPV

- Fresh air inlet flap

- Dust filter with rotary valve outlet

- Waste gas stack with fan

- Discharge conveyor belt

Drying technology

Processing of minerals involves a number of process steps, such as crushing, sizing, classifying and sometimes the need for drying. Removing moisture from a given material is, in itself, relatively straightforward; you just have to introduce hot air. Although this can be calculated with a high level of accuracy, the drying step presents its own unique and sometimes difficult challenges; high diversity in the raw materials, changing material characteristics during the drying process and the true amount of time that is needed in order to achieve the desired goal. Achieving the optimum solution takes know-how, years of proven experience, and the correct equipment technology – and HAZEMAG has the capabilities to deliver highly competent solutions.

Drying / Drying and Grinding Combination

The decision to dry a particular material, or alternatively to dry and then grind it, is driven by the final product goal, and every industry presents a potential need and opportunity for rapid drying technology. For example:

- Cement: clay, trass, chalk, pozzolana, opoka, blast-furnace slag, marl

- Gypsum: FGD gypsum, chemical gypsum, anhydrite

- Ceramic: clay, kaolin, bentonite

- Building/Construction: flue ash, sand

- Chemical: aluminium hydroxide, fluorite, tricalcium phosphate filter cake, dicalcium phosphate filter cake, chrome hydroxide filter cake, nickel carbonate filter cake, chrome ore

- Steel: zinc sludge, blast-furnace slag, iron ore concentrate

- Lime: limestone, dolomite, gypsum

Drying in this sense is the thermal extraction of water from wet material. Drying takes place by convection, in a high-speed dryer – hot gas in contact with the material to be dried causes vaporisation/evaporation of the water. Flue gases from a hot gas generator are usually used, but exhaust gases that may be present on site can also be used. The fuel source for the gas generator is generally natural gas, heating oil or coal fines/dust.

In order to determine the optimum drying solution, the following important points, among others, should be considered and evaluated.

The characteristics of the material; before and after drying in the rapid dryer

It is important to know and understand the condition of the material in its “wet state” in order to provide the knowledge needed for design and selection of the feed equipment. It is also important to know and understand the condition of the material in its “dry state”, thus providing the required knowledge for the design and selection of the product discharge equipment.

Integration of the drying process

The drying process in the rapid dryer requires careful planning; taking into consideration the material handling steps that precede drying and the subsequent steps that will following drying. The complete process must be synchronised; ensuring a smooth, efficient and uninterrupted process.

Properties of the material to be dried

Selection of a Rapid Drying system is only possible with a full understanding of the properties of the material that must be dried. For example:

- Ability to absorb water

- Consistencies

- Size

- Abrasiveness

- Stickiness

- Thixotropy

Knowledge of these properties is essential in determining and selecting the optimum drying solution.

The required / available space

In many cases, the need for the drying process is constrained by the amount space available within the processing plant. The solution to this problem can be achieved through experience, a range of processing solutions, and an industry proven partner.

Mode of operation; constant or interrupted

Knowing the desired or required mode of operation also plays an important role in determining the selection and design of the drying system. This knowledge ensures that the drying plant models the necessary function and material flow.

Installation height of the plant

Installation height must be considered and will be influenced by the flow rates of the hot gas and exhaust gas.

The Drying Plant: Key Component Breakdown

- Feed / handling equipment for the wet material

- Hot gas generator

- Dryer

- Dryer air flow locks; feed and discharge points

- Filter house for de-dusting

- Conveying equipment

- Tubing / Ductwork

- Electrical Instrumentation & Controls (EI&C)

Knowledge of the process parameters in respect of the drying process is also a basic requirement, but any physical and/or chemical changes in the material to be dried also have to be taken into account.

- ADS

- ASS