Key Features

TERTIARY IMPACTOR HTI

TECHNICAL DATA

TERTIARY IMPACT CRUSHER HTI

| Type | Rotor dimensions ɸ x width [mm] | Capacity * [t/h] | max. edge- length of lump [mm] * | Inlet height x width[mm] | Installed Power* [kW] | Weight [kg] | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| HTI 1005 | 1.010x500 1) | 40-60 | up to 70 3) | 175x510 | 90-132 | 6.900 1) | ||||||

| 1.010x500 2) | 40-60 | up to 150 4) | 260x510 | 110-200 | 7.800 2) | |||||||

| HTI 1010 | 1.010x1.000 1) | 90-120 | up to 70 3) | 175x1.020 | 200-250 | 10.000 1) | ||||||

| 1.010x1.000 2) | 60-120 | up to 150 4) | 260x1.020 | 160-315 | 11.900 2) | |||||||

| HTI 1014 | - | - | - | - | - | - | ||||||

| 1.010x1.340 2) | 120-160 | up to 150 4) | 260x1.360 | 200-315 | 13.500 2) | |||||||

| 1) VR2-Rotor, weight without grinding path | ||||||||||||

| 2) VR4-Rotor, weight with grinding path | ||||||||||||

| 3) max. feed size to produce sand | ||||||||||||

| 4) max. feed size to produce chippings | ||||||||||||

| *values are variable and can be aligned to the particular requirements | ||||||||||||

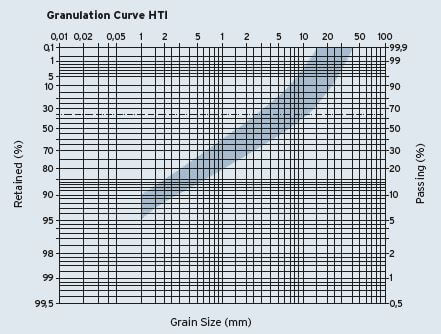

Granulation Curves

PRODUCT DESCRIPTION

The HTI series was designed for the economic tertiary crushing of hard rock. It’s a modular system, manufactured with the objective of fulfilling every task in the bulk materials industry. The machine’s fittings, as well as its control, may be adapted to suit operators’ individual requirements – including fully automatic mode.

Depending on the properties of the feed material, the crushing ratio, and desired specification for product grain size, feed sizes of up to 150mm and throughput rates up to 160 t/h are possible.

HAZEMAG HTI – the innovation for the production of crushed stone fines and high-quality stone chippings.

Due to the continuous pursuit of procedural, maintenance and user-friendly improvements, a new development emerged in the field of tertiary machines: The HAZEMAG Tertiary Impact Crushers of the HTI series. The new HAZEMAG concept for tertiary crushing unites our know-how of more than 60 years, combined with the practical experience and the requirements of the plant operators.

ROTOR The rotor of the Impact Crusher is generally the component which is put under the most stress during the crushing process. Depending on the crushing problem to be solved, two types of rotors are available for the HTI series.

VR2-Rotor

- Maximum feed size: 70 mm

- Ideal for the production of crushed sand

- Fitted with two rows of blow bars

VR4-Rotor

- Maximum feed size: 150 mm

- Ideal for the production of high-quality chippings

- Fitted with four rows of blow bars

For service, inspection and maintenance work the machine’s housing is fitted with large doors on both sides. The blow bars are laterally inserted into the rotor, so that they can be simply and quickly exchanged. The housing’s plating largely consists of accessible and easy to exchange wear plates.

The new design of the HAZEMAG HTI series can provide significant reductions in operating and maintenance costs.

Standardisation of wear parts has been a key factor in the design of HTI series, and economical replacement of wear parts is guaranteed. The exceptionally wear-resistant blow bar materials are designed to give utilisation in excess of 50% and, because of the symmetrical design of the HTI Impact Crusher, the rotor’s direction of rotation can be reversed. Operating the HTI Impact Crusher in the reverse direction This feature has a positive effect on the crushing performance and service life of the wear elements. Switching the direction of operation has the effect of automatically regrinding the blow bars, which ensures a more uniform utilisation, and makes for a more consistent product. The design of the crushing chamber of the HTI series, and easily adjustable impact apron gap, ensures optimum crushing and reduced energy consumption.

Hydraulic suspension of the Impact Apron

Hydraulic suspension of the impact apron allows for quick and simple adjustment of the gap setting and adaptation to suit specific process conditions.

As an option, the HTI series can be fitted with a grinding path to restrict the amount of oversize, and to promote the generation of a cubical and stress-free product.

With the HAZtronic system, the crusher can be controlled and adjusted from the main control panel. All settings that determine the end product can be input and called up at the touch of a button, without interrupting operation. This allows immediate reaction and adjustment to suit varying operating conditions, at any time, to ensure optimum productivity.

- AP-VHM-R

- AP-KVH-R