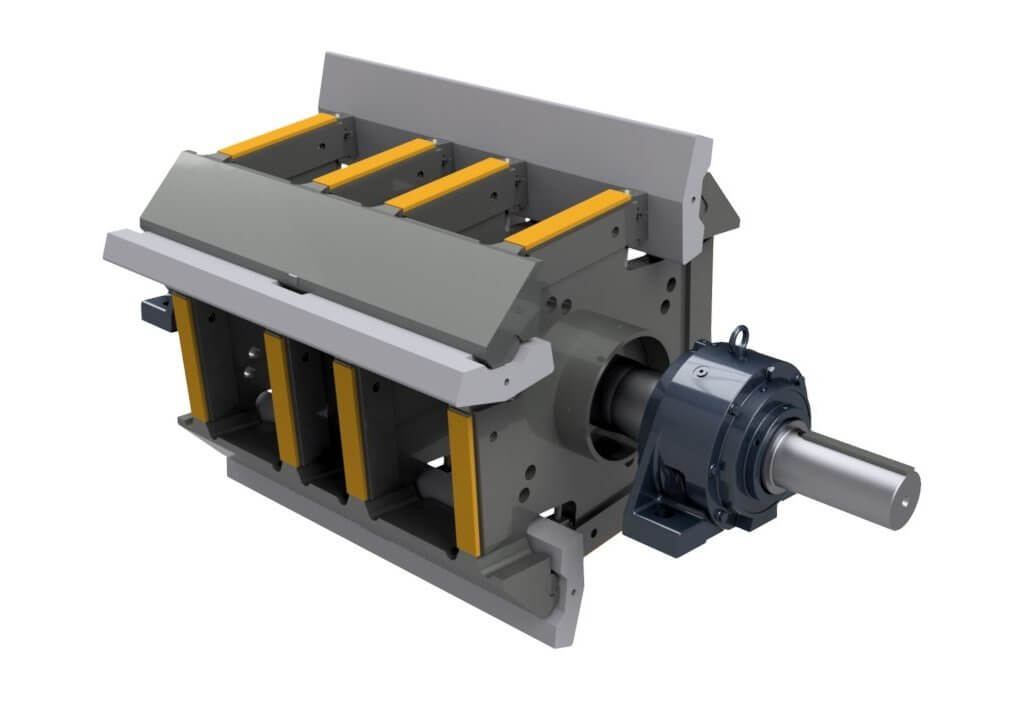

B-Rotor

HAZEMAG’s B-Rotor is a completely closed rotor with blow bars that are bolted onto retaining bars, which are welded in place, and can be reversed after one side has been worn down.

Key benefits:

- Low-cost construction

- Easy-to-change blow bars

GSK-Rotor

His patented rotor is HAZEMAG’s own design and is a cast and welded steel construction, with individually cast rotor discs, to accommodate the proprietary blow bars as primary crushing implements. The blow bars are locked in position in the holders by means of wedges, which can be easily removed for blow bar replacement.

The GSK-Rotor is a cast and welded construction with cast steel discs welded to the rotor body. The blow bars are mechanically wedged in position. The design of the rotor and blow bars enables blow bars to be changed in the radial and axial direction using a compatible blow bar changing device.

This type of construction can also be retrofitted as a replacement rotor in many HAZEMAG impact crushers, as well as in other manufacturers’ crushers.

Key benefits:

- Wear-optimised rotor design

- Blow bars are 60-80% more efficient

- Cheaper to manufacture than an S-Rotor

- Combines the advantages of the S and K blow bars

- Good impact effect

- Easy change of blow bars in axial and radial direction

- Enhanced workplace safety

- Reduced labour cost for blow bar replacement

KS-Rotor

The KS-Rotor is designed as an open disc rotor which can be installed and used in all generations of HAZEMAG secondary impact crushers. The rear retaining bar fits into corresponding recesses in the rotor discs, and the one-piece longitudinal retaining bar absorbs crushing and centrifugal forces from the blow bars. A reinforced retaining bar is installed as an extension to the K-Rotor. Blow bars are locked in place with a clamping wedge.

The basic rotor body, blow bars and blow bar position retain tried and tested geometry and construction, and wear protection and flexibility of use have been significantly improved.

Key benefits:

- High flexibility when changing blow bars

- Easy positioning of clamping wedges

- Improved wear protection

- Improved operational flexibility

QB-SP-Rotor

The design of the QB-SP-Rotor is identical to that of the KS-Rotor, but it is significantly heavier; making this rotor ideal for difficult shredding applications, such as larger feed sizes or construction waste.

Key benefits:

- Good degree of blow bar utilisation

- QB-SP wedges facilitate blow bar changing in axial and radial direction

- Robust rotor body construction

S-Rotor

The S-Rotor has a completely closed rotor body. Screwed-on contact strips or build-up welds on the rotor body serve as protection. The laterally inserted blow bars are locked in the axial direction. They also lie loosely in the holder during use and can be reversed when one side becomes worn. The S-shape of the blow bar helps to achieves a cubic end grain.

Key benefits:

- Robust construction

- Excellent cubicity of end grain

SQ-Rotor

The SQ-Rotor is an open disc rotor with stable support beams. The rotor improves the shape of the end grain and the shredding efficiency with less wear. The geometry of the blow bar improves the degree of utilisation by around 20% compared to the S blow bar. The SQ rotor combines the shredding advantages of the S and Q blow bars in terms of utilisation. Replaceable wear plates are attached to the side.

Key benefits:

- Good degree of blow bar utilisation

- Good impact effect

- Q-SP wedges facilitate blow bar changing in axial and radial direction

- Replaceable wear protection plates

VR2-Rotor

The VR2-Rotor is an open disc rotor which can be driven from both sides – giving the rotor impressive flexibility in application options. Replaceable, rotatable and interchangeable wear protection caps can be changed easily and flexibly, and the design of the blow bar holder enables different thicknesses of blow bars to be installed; allowing the rotor to be adapted to suit changes in production conditions.

Key benefits:

- Improved wear protection during production compared to KV-Rotor

- Flexible application possibilities

- Rotatable and interchangeable wear protection caps

- Different blow bar thicknesses can be used (40mm, 60mm & 75mm)

- The 75mm blow bar is also available with a ceramic insert

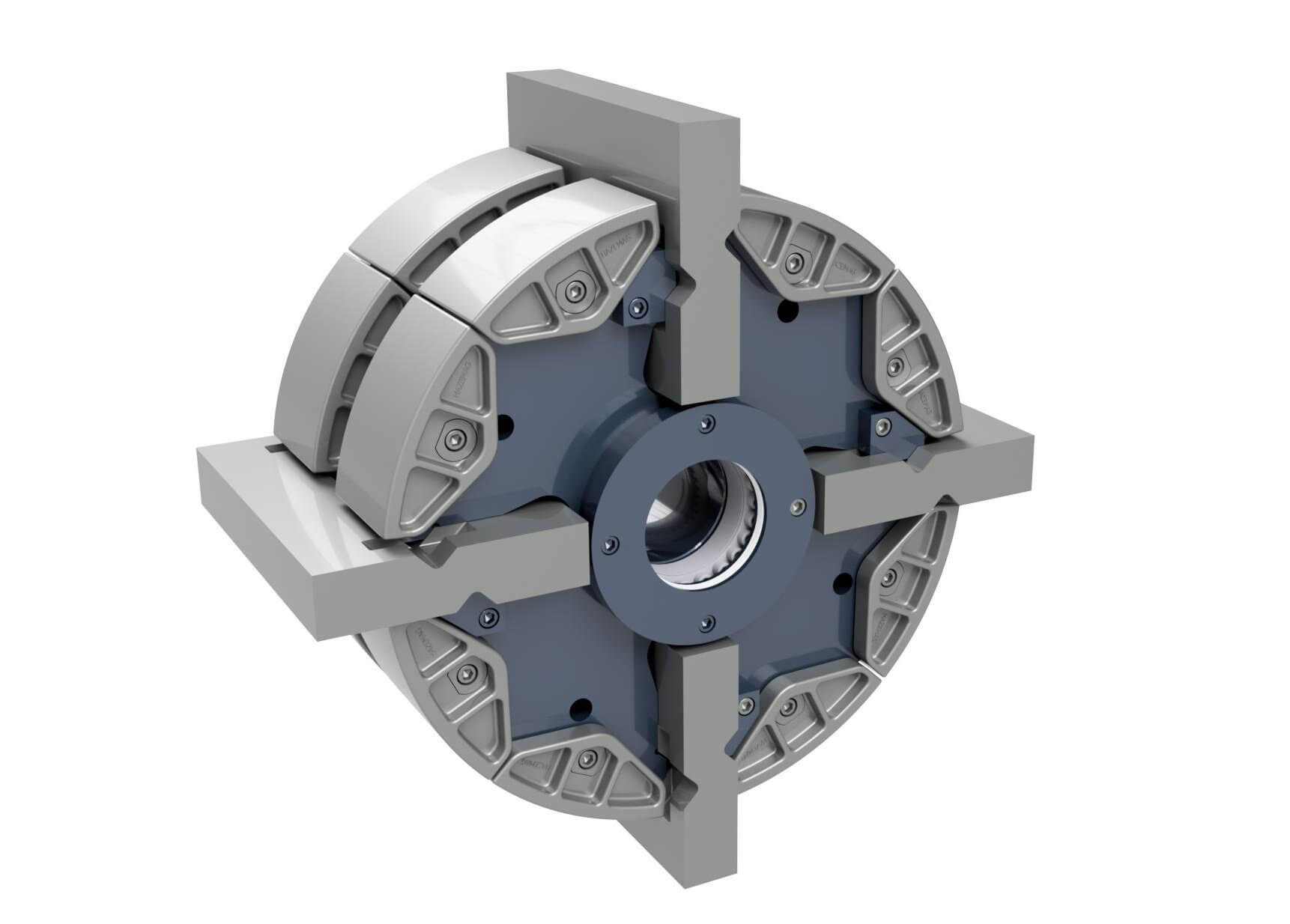

VR4-Rotor

This newly-developed rotor design will significantly increase the availability of your HAZEMAG Impact Crusher. The application of replaceable and rotatable wear caps has replaced the use of traditional, time-consuming and costly wear material. Simple and regular replacement of the wear caps facilitates significant reduction in maintenance requirements. In addition, we have further increased utilisation of your HAZEMAG Impact Crusher by optimising the shape of the blow bars.

Key benefits:

- Wear mass of blow bars is increased by 12.5%

- Innovative wear parts concept offers ergonomic and safe operation

- Significant increase in wear mass of the wear caps compared to conventional systems

- Wear protection caps are easy to disassemble and quick to replace

Stefan Wewers

Leiter Kundendienst / Head of Customer Service

HAZEMAG & EPR GmbH

Brokweg 75

48249 Dülmen – Germany

T: +49 2594 77 487

F: +49 2594 77 401

M: +49 171 7417670

stefa1722031158n.wew1722031158ers@h1722031158azema1722031158g.de1722031158