Key Features

ROLLCRUSHER HRC

TECHNICAL DATA

ROLL CRUSHER | HRC

| Type | Maximum Capacity [t/h] | Inlet Size [mm] | Maximum Feed Size [mm] | Rotor Size D x W [mm] | Weight [kg] |

|---|---|---|---|---|---|

| HRC 0505 | 200 | 250 x 530 | 225 | 520 x 510 | 3.750 |

| HRC 0507 | 300 | 250 x 730 | 225 | 520 x 710 | 5.000 |

| HRC 0510 | 400 | 250 x 1.040 | 225 | 520 x 1020 | 6.250 |

| HRC 0605 | 300 | 650 x 550 | 300 | 680 x 510 | 7.500 |

| HRC 0607 | 400 | 650 x 750 | 300 | 680 x 710 | 8.000 |

| HRC 0610 | 600 | 650 x 1.060 | 300 | 680 x 1.020 | 15.000 |

| HRC 0616 | 900 | 650 x 1.570 | 300 | 680 x 1.530 | 25.000 |

| HRC 0620 | 1.200 | 650 x 2.080 | 300 | 680 x 2.040 | 27.500 |

| HRC 0810 | 750 | 850 x 1.060 | 400 | 850 x 1.020 | 22.500 |

| HRC 0816 | 1.200 | 850 x 1.570 | 400 | 850 x 1.530 | 30.000 |

| HRC 0820 | 1.550 | 850 x 2.080 | 400 | 850 x 2.040 | 40.000 |

| HRC 1010 | 850 | 1.050 x 1.060 | 400 | 1.050 x 1.020 | 35.000 |

| HRC 1016 | 1.300 | 1.050 x 1.570 | 400 | 1.050 x 1.530 | 42.500 |

| HRC 1020 | 1.750 | 1.050 x 2.080 | 400 | 1.020 x 2.040 | 50.000 |

| HRC 1210 | 1.050 | 1.280 x 1.090 | 500 | 1.280 x 1.050 | 30.000 |

| HRC 1216 | 1.550 | 1.280 x 1.690 | 500 | 1.280 x 1.650 | 45.000 |

| HRC 1220 | 2.100 | 1.280 x 2.090 | 500 | 1.280 x 2.050 | 70.000 |

| HRC 1225 | 2.600 | 1.280 x 2.590 | 500 | 1.280 x 2.550 | 80.000 |

| HRC 1230 | 3.100 | 1.280 x 3.090 | 500 | 1.280 x 3.050 | 90.000 |

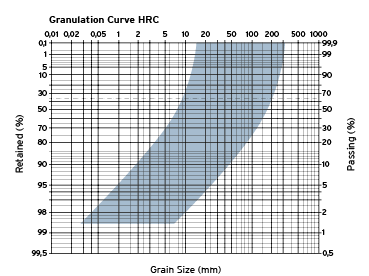

Granulation Curves

PRODUCT DESCRIPTION

For industrial beneficiation of primary and secondary raw materials, selection of the most appropriate crushing method plays a key role in the production of specific grain sizes, shapes and surfaces, or to break down multi-component materials.

The selected crusher must conform to today’s stringent requirements for processing rocks, ores and coals. Materials to be crushed are becoming more and difficult to process, high throughput capacities are required. High focus is now placed on energy consumption, and the use of energy-efficient roll crushers, with high throughput rates, is becoming increasingly important from an economic and ecological point of view.

HAZEMAG Roll Crushers offer significant features and benefits:

- Low specific power requirement

- High to very high throughput rates

- Intelligent design with tramp metal protection

- Automatic gap setting

- Easy maintenance

- Wide range of crushing tools

- Cubicle product with minimal fines

- Trouble-free operation with very sticky and moist materials

- Suitable for adhesive feed material

Roll Crusher operation is based on the principle of continuous pressure generated between two counter-rotating rolls; allowing uninterrupted crushing, in contrast to the intermittent action of jaw crushers. During operation, the high rotational energy of the crushing rolls and the drive components reduces peak loads, resulting in a more regular level of power consumption.

If non-breakable tramp metal is present in the feed material, it is essential that the crushing gap can open to let the tramp material pass. This is achieved by employing a ‘floating roll’, which is mounted in pivoting rocker arms. The rocker arms are supported by the lower housing via hydraulic cylinders. In order to guarantee parallel retraction of the floating roll, a torsion shaft connects the two rocker arms. The rotational reaction of the floating roll allows an almost seamless movement and creates a wide escape path.

HAZEMAG Roll Crusher housings and drive mountings are robustly-designed for heavy-duty applications. They are fitted with easily replaceable wear parts, with removable maintenance hoods below the feed hopper enabling quick and easy exchange of crushing segments.

The drive is assembled on a base frame, which is connected with the roll crusher. The floating roll drive, also supported in pivoting mode, is connected with the floating roll rocker arm by a coupling rod. This ensures that a constant drive belt tension exists during the retraction movement of the floating roll, and during gap adjustment.

The crushing rolls for primary and secondary crushers comprise a polygonal roller body equipped with exchangeable crushing segments. Unique geometry between the roller body and crushing segments, achieves an optimal, form-fitting attachment, allowing them to withstand the high crushing forces. The shape and number of teeth are determined by the respective application.

With the standard PLC control the crushing gap, and therefore the product, can be controlled and monitored from the control room as well as from the switchgear cabinet on the crusher. With this system, the crushing gap can be reduced very easily – just by the push of a button – to compensate for wear of the crushing tools.

Examples of raw materials that can be processed with HAZEMAG Roll Crushers include limestone, clay, gypsum, coal, coke, phosphate, marl, chalk, salts and quicklime.

Further features of the HAZEMAG Roll Crusher include:

- Rotation and slip monitoring of the crushing rolls

- Temperature monitoring of bearings, gearbox and hydraulic unit

- Roller carriage for moving the roller crusher to the maintenance position

- Quick exchange of crushing segments even in operating position

- Adjustable scrapers