Key Features

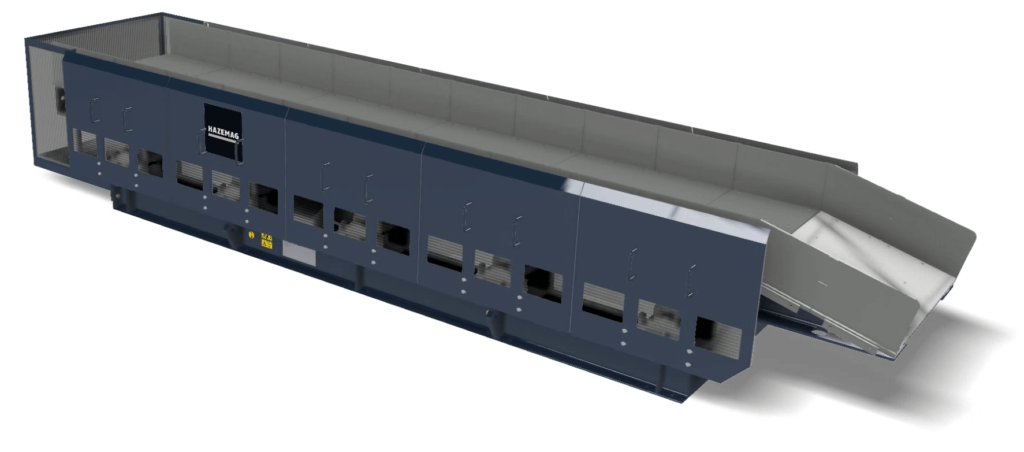

PUSH FEEDER HPF

TECHNICAL DATA

PUSH FEEDER | HPF

| Type | Width x Length [mm] | Max. Feed size [mm] | Throughput rate* [t/h] | Installed capacity [kW] | Weight [kg] |

|---|---|---|---|---|---|

| HPF 1045 | 1.000 x 4.500 | 700 | 250 | 22 | 7.000 |

| HPF 1365 | 1.300 x 6.500 | 1.000 | 550 | 55 | 10.500 |

| HPF 1665 | 1.600 x 6.500 | 1.250 | 800 | 55 | 11.500 |

| HPF 1870 | 1.800 x 7.000 | 1.600 | 1.200 | 75 | 13.500 |

*depends on stroke and stroke frequency – may be largely adapted to the respective requirements

PRODUCT DESCRIPTION

HAZEMAG Push Feeders HPF are used mainly in the Minerals Processing and Cement & Aggregates industries.

What makes the HAZEMAG Push Feeder HPF so special?

Made in Germany, HAZEMAG Push Feeders are heavy-duty, durable, low-wear machines, and one of the most robust discharge units for concrete and steel feed hoppers. Capable of operating either horizontally or on an incline, the HAZEMAG Push Feeder essentially consists of a frame, of solid steel construction, and a robust push table equipped with replaceable wear plates.

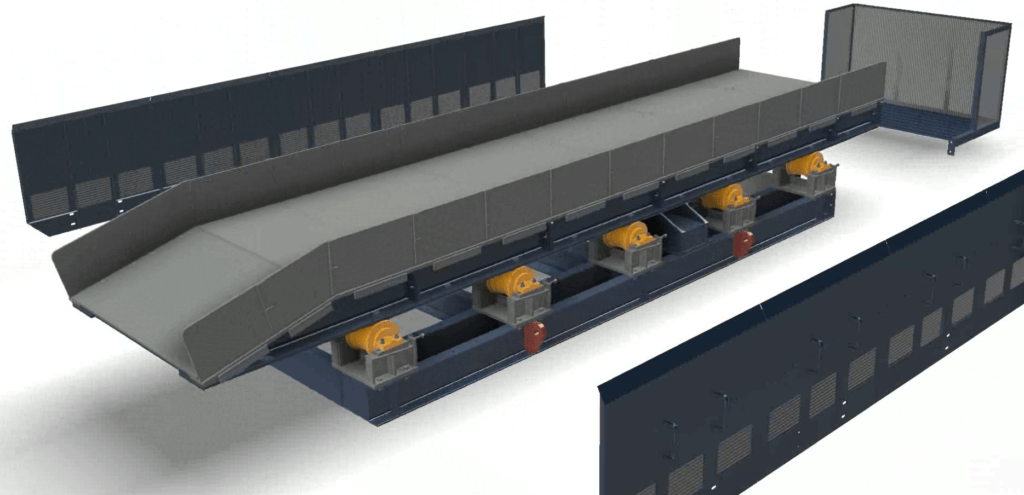

At the heart of the HAZEMAG Push Feeder is the durable hydraulic drive, with an optimally positioned hydraulic cylinder. The hydraulic drive ensures that error-free material transport is guaranteed by the forward and backward movement of the push table, with a stroke frequency that can be adjusted to meet your needs.

The push table is mounted on solid rollers which, in conjunction with the specially developed rails, guarantee long and trouble-free operation. A total of 10 rollers are mounted below the push table to evenly support the load of the table. The armoured rollers are adjusted by a specially-developed adjustment device so that they are constantly in contact with the running rails.

The rollers are equipped with sealed and permanently lubricated bearings, eliminating the need for regular maintenance, and the track rails, developed by HAZEMAG, are manufactured from low-wear materials. This combination of robust rollers and running rails makes the HAZEMAG Push Feeder easy to maintain and very economical to operate.

When the hydraulic cylinder advances the push table, material is carried along from the feed hopper. When the push table moves back, the feed material breaks off at the push table’s discharge point, from where the material is fed directly, or via a chute, to the downstream machine.

When the feed table is moved back, material is pushed against the rear wall of the hopper, and it can only function effectively if there is sufficient height and volume of material in the hopper. The exceptionally robust construction of the HAZEMAG Push Feeder allows it to move a very deep layer of material; thereby maximising throughput capacity.

Conveying capacity of the HAZEMAG Push Feeder HPF is primarily determined by three factors:

- Width of the Push Feeder

- Stroke Length of the Push Table

- Feed Material

Push Feeder Width

Selection of the ideal width of Push Feeder is the primary factor in determining conveying performance.

HAZEMAG’s range of Push Feeders comprises four standard sizes, with widths ranging from 1,000mm to 1,800mm.

HPF 1045 | HPF 1365 | HPF 1665 | HPF 1870

Stroke Length

The second essential factor is the stroke length of the Push Table: HAZEMAG Push Feeders have a pushing distance which is also optimally matched to the respective plant conveyor capacity. The biggest advantage of a HAZEMAG Push Feeder is the stepless adjustment of the stroke distance, achieved through the use of the most modern hydraulics and corresponding control system; enabling operators to react quickly to changing requirements.

Feed Material

The third factor is the Feed Material: The respective feed size, in combination with the optimal width of the Push Feeder, as well as the optimally adapted and adjustable stroke, guarantees high throughput rates.

HAZEMAG Push Feeder – Pushing the Limits!