Our impact crushers

HAZEMAG Impactors: The heart of stationary, semi-mobile and mobile crushing plants.

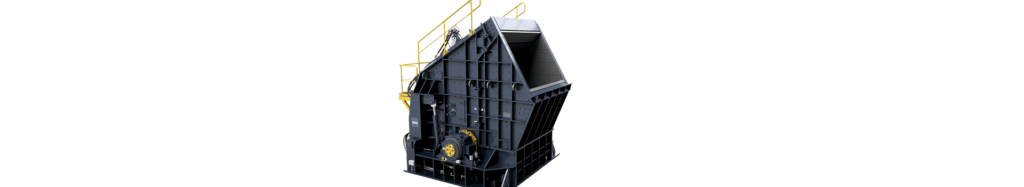

PRIMARY IMPACTORS FOR CEMENT, LIMESTONE, GYPSUM…

HAZEMAG can supply the most suitable impactor for practically every primary crushing application. Our single and double-rotor impactors process large feed sizes at high throughput rates at optimum degrees of crushing efficiency. A continuous equipment development programme ensures minimum wear, maximum availability, very low maintenance requirements and extreme flexibility regarding establishment of machine and product parameters.

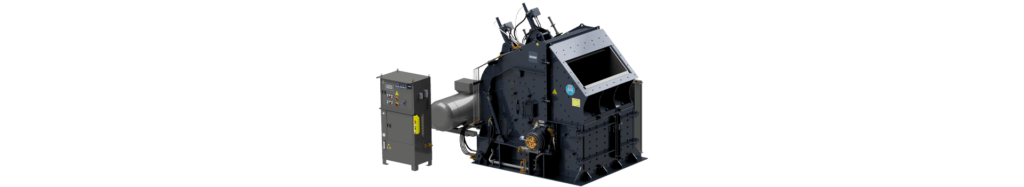

IMPACTORS FOR SECONDARY AND HARD ROCK CRUSHING

HAZEMAG Impactors for Secondary Crushing applications embody a combination of modern equipment design, highly developed hydraulics, and the latest control systems. The unique HAZtronic® system enables the operator to meet exact customer demands for specific product granulometries according to a wide range of recipes. The innovative design of individual components provides for minimum maintenance coupled with a high degree of reliability and flexibility.

HAZEMAG Hard Rock Impactors have been specially developed to crush abrasive materials. In order to minimise wear costs, particular emphasis has been placed on the use of highly wear-resistant materials and ease of replacing wear parts.

HAZEMAG can provide the appropriate machine, or appropriate complete plant, whatever the primary crushing application may be: stationary, semi-mobile, mobile. HAZEMAG impact crushers can handle individual lumps of feed material up to 8 tons in weight and 3 m3 (100 cu.ft) in volume, effecting the comminution process in a single pass at capacities of over 2200 tons/hour. Even feed material with a high moisture content up to 15% H2O can be processed without any problems by the provision of indirect heating of feed plates and impact aprons through installation of a circulating thermal oil heating system.

HAZEMAG impact crushers are insensitive to unbreakable inclusions in the feed material thanks to pendulum-mounted impact aprons. They can be retractable, mechanically mounted or controlled by hydraulic cylinder for manual or automatic adjustment of gap settings to determine product size.

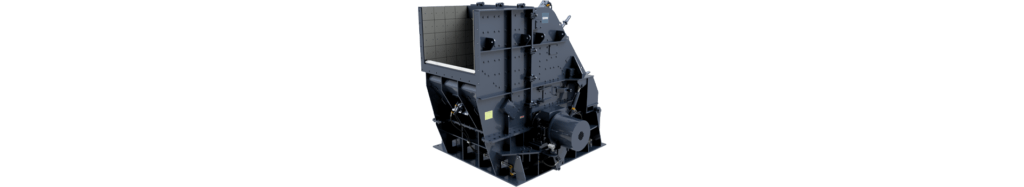

HAZEMAG recognised many years ago the need for equipment specifically designed for the processing of rubble and similar materials, and developed the appropriate impactors based on their well-proven non-metallic minerals processing equipment. Meanwhile, the 3rd generation of rubble recycling impactors is now in service, this latest design being characterised by the hydraulically actuated impact apron mounting and adjustment, together with its electronic control system. This concept improves considerably the flexibility of the impactor adjustment, at the same time minimising the hazard of blockages and damage caused by tramp metal.

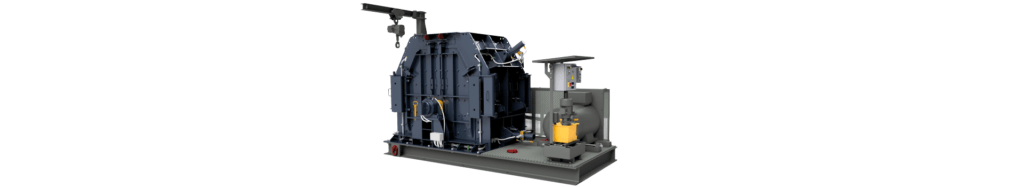

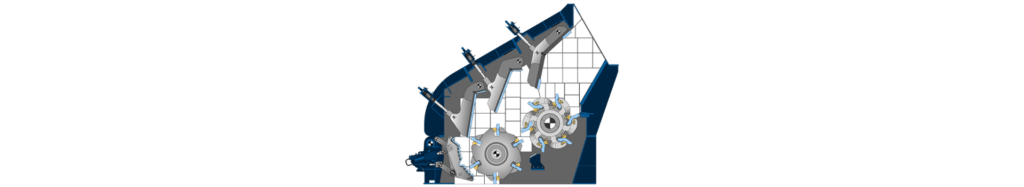

PRIMARY AND SECONDARY CRUSHING IN ONE MACHINE

The compound crusher was developed to avoid the problems and the investment of a closed-circuit operation. The arrangement of two rotors, both turning in the direction, results in the very high reduction of its system.

The product, which is obtained without any grates from blasted coarse “Run of Quarry” feed material, is a perfect ball mill feed with more than 90% minus 25 mm (1”1 ). Furthermore, the Compound crusher produces a large amount of minus 10 mm (3/8”), which also reduces the load on the ball mill resulting in considerable savings of operating costs.