Key Features

HAMMER CRUSHER HDS

TECHNICAL DATA

HAMMER CRUSHER HDS

| Rotor | Capacity* | Installed Power | ||||||

| Model | Diameter mm | Width mm | Max. Edge Length mm | 95% <25mm t/h | 95% <90mm t/h | Product 95% <30mm | Product 95% <30mm | Weight kg |

| HDS 1412 | 1.400 | 1.200 | 1.000 | 180 | 280 | 2x 132 | 2x 160 | 30 |

| HDS 1414 | 1.400 | 1.400 | 1.000 | 220 | 340 | 2x 160 | 2x 200 | 35 |

| HDS 1416 | 1.400 | 1.600 | 1.000 | 260 | 400 | 2x 200 | 2x 250 | 37 |

| HDS 1418 | 1.400 | 1.800 | 1.000 | 300 | 460 | 2x 250 | 2x 315 | 40 |

| HDS 1613 | 1.600 | 1.320 | 1.200 | 330 | 475 | 2x 250 | 2x 315 | 55 |

| HDS 1615 | 1.600 | 1.540 | 1.200 | 380 | 560 | 2x 315 | 2x 355 | 58 |

| HDS 1618 | 1.600 | 1.760 | 1.200 | 450 | 670 | 2x 355 | 2x 400 | 61 |

| HDS 1620 | 1.600 | 1.980 | 1.200 | 550 | 830 | 2x 400 | 2x 500 | 65 |

| HDS 1818 | 1.800 | 1.840 | 1.400 | 550 | 800 | 2x 400 | 2x 500 | 87 |

| HDS 1821 | 1.800 | 2.070 | 1.400 | 660 | 1.000 | 2x 500 | 2x 630 | 96 |

| HDS 1823 | 1.800 | 2.300 | 1.400 | 780 | 1.225 | 2x 630 | 2x 710 | 104 |

| HDS 1825 | 1.800 | 2.530 | 1.400 | 900 | 1.450 | 2x 710 | 2x 880 | 112 |

| HDS 2019 | 2,000 | 1,880 | 1,600 | 1000 | 1475 | 2x 800 | 2x 880 | 113 |

| HDS 2022 | 2,000 | 2,200 | 1,600 | 1150 | 1650 | 2x 880 | 2x 1100 | 121 |

| HDS 2025 | 2,000 | 2,520 | 1,600 | 1350 | 1850 | 2x 1000 | 2x 1100 | 130 |

| HDS 2028 | 2,000 | 2,840 | 1,600 | 1550 | 2150 | 2x 1250 | 2x 1250 | 138 |

| HDS 2032 | 2,000 | 3,160 | 1,600 | 1750 | 2450 | 2x1400 | 2x1400 | 146 |

| *values are variable and can be aligned to the particular requirements | ||||||||

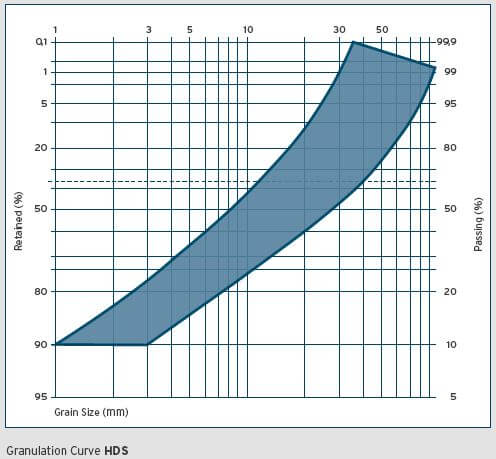

Granulation Curves

PRODUCT DESCRIPTION

Double-shaft hammer crushers are mainly used in the cement industry for the comminution of soft to medium-hard, but also tough and cohesive materials: Chalk, Limestone, Gypsum, Clay and Marl, and Coals such as Anthracite, Bituminous and Lignite. Crushing of the feed material is achieved by percussion, impact and shear forces.

Two counter-rotating rotors crush feed material edge length of up to 1,600 mm. An anvil is located centrally between the two rotors, which directs the processed material onto grate baskets. These grates, which serve to restrict the amount of oversize, are mounted on a grate carriage and can be completely withdrawn from the crusher housing for servicing and maintenance purposes.

Each rotor comprises a central shaft onto which discs are fixed across the full width of the crusher. Between the discs, free-swinging hammers are mounted on hammer bolts and secured at both ends to the outer discs. Rotation and replacement of the hammers is facilitated by a hydraulic bolt removal tool together with a special lifting device.

The feed material is processed in three stages:

- The first stage reduction is by percussion and impact as the material to be crushed is gravity-fed from above the hammer circle.

- The material is then directed to the anvil, where it is crushed further by percussion and shear forces.

- The material flow then spreads across the discharge grates and, if the correct product granulometry has been achieved, it is separated and discharged through the grates. The grate bar gap spacing determines the final product size, and any remaining material continues to be processed until it can pass through the grate gap.

A rotor turning device is supplied with HAZEMAG HDS Hammer Crushers to enable the rotor to be turned and locked in the correct position for hammer replacement. The hammers are fitted into a holding device and secured in position then, with the aid of a hydraulic bolt removal tool, the hammer bolts can then be extracted and/or inserted.

- AP-P

- AP-PM

- AP-PMH