Our Roll Crushers

HAZEMAG roll crushers are ideally suited to the selective crushing of soft- to medium-hard materials with a low percentage of fines in the product. They have also proved their effectiveness in the crushing of cohesive materials with a high moisture content.

Fields of Application HAZEMAG roll crushers have been installed in plants as primary and secondary crushers for the comminution of raw materials such as limestone, clay, flint clay, coal, coke, phosphate, marl, chalk, and filler material as well as burnt lime, foam concrete, fertilizer and much more. Roll crushers with differing tooth configurations can handle feed material of up to 1500 mm to generate a product of some 250 mm at rates of up to 2500 t/h. Roll crushers with smooth rolls are used for pulverization to generate a product granulometry of ≤ mm.

To provide optimum protection for the roll crusher, a hydraulic floating roll retraction system has been developed based on the successful system used in HAZEMAG impact crushers.

According to the product required, the roll is retained hydraulically in position with a precise and constant gap setting, thereby guaranteeing a product of uniform quality.

If a large piece of non-crushable material enters the crusher, the floating roll overrides a set rated pressure and retracts hydraulically, allowing the foreign body to pass through, immediately after which the roll returns to its original set position. Thus, any potential damage to the crusher is avoided and at the same time the amount of product oversize resulting from the retraction operation is reduced to a minimum.

If a large piece of non-crushable material enters the crusher, the floating roll overrides a set rated pressure and retracts hydraulically, allowing the foreign body to pass through, immediately after which the roll returns to its original set position. Thus, any potential damage to the crusher is avoided and at the same time the amount of product oversize resulting from the retraction operation is reduced to a minimum.

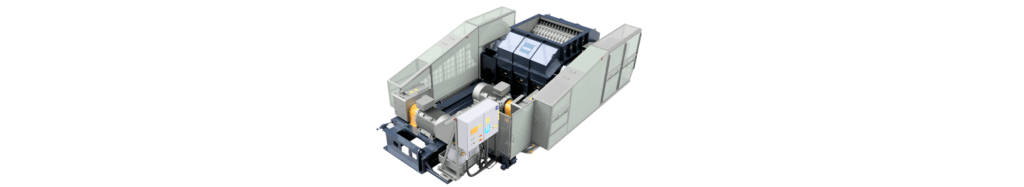

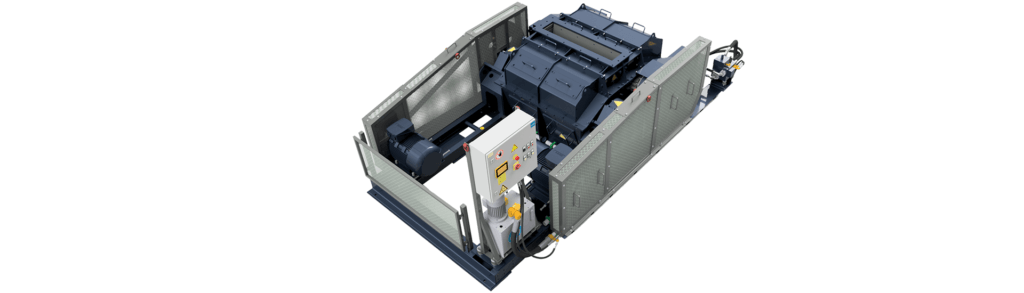

The crushing of the feed material in roll crushers is affected essentially by pressure between two counter-rotating rolls. Thanks to the distinctive geometry of the roll surface, i.e., teeth, hard facing, etc., the feed material is drawn into the crushing gap between the rolls. To meet customers‘ specific product requirements, there is a wide range of crushing segments available, which are quick and easy to exchange. The fixed roll is mounted in self-aligning roller bearings and is secured in the housing lower section. The floating roll is mounted in rocker arms, hydraulically supported against the housing lower section. In order to guarantee parallel retraction of the floating roll, the rocker arms are connected to one another by a torsion axle. The crushing chamber of the housing is lined with wear plates. The upper section of the housing can be easily removed for the dismantling of the rolls or the changing of the crushing segments and is also provided with service doors. The drive is affected by electric motor, gearing and vee belts, and can be allied to the site installation situation of the customer. The floating roll drive is connected by coupling rod to the floating roll rocker arms, so that the vee-belt tension remains constant during any retraction movements.

Because of the individual characteristics of the various feed materials, prior tests on these materials are often paramount in order to ensure optimum selection of the most suitable roll crusher. For such tests, a roll crusher is available in HAZEMAG’s own state of the art test facilities, by means of which crusher gap settings, rotor tip speeds, power consumption, crushing teeth geometry and other important parameters can be established. The information gathered during such tests is instrumental in determining the correct choice of machine and thus providing a sound basis for any investment decision.