Key Features

FLAP GATES HPV/HGV

TECHNICAL DATA

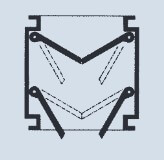

PENDULUM FLAP GATE HPV

| Type | Inlet/Outlet [mm] | Throughput rate [m3/h] | Feed size [mm] | Installed Power* [kW] | Weight [kg] | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| HPV 33 | 330 x 330 | 5 | 80 | 0.55 | 200 | |||||

| HPV 44 | 390 x 410 | 7 | 100 | 1.1 | 350 | |||||

| HPV 55 | 500 x 500 | 13 | 130 | 1.1 | 400 | |||||

| HPV 66 | 560 x 597 | 30 | 150 | 2.2 | 760 | |||||

| HPV 610 | 560 x 997 | 50 | 150 | 2.2 | 870 | |||||

| HPV 615 | 560 x 1.497 | 75 | 150 | 2.2 | 1.030 | |||||

| HPV 810 | 800 x 1.000 | 90 | 300 | 4.4 | 2.300 | |||||

| HPV 815 | 800 x 1.500 | 150 | 300 | 4.4 | 2.695 | |||||

| HPV 1015 | 1.000 x 1.490 | 200 | 350 | 5.5 | 3.450 | |||||

| HPV 1020 | 1.000 x 1.990 | 265 | 350 | 5.5 | 4.410 | |||||

| *The weight specifications refer to 2 segments (flaps) | ||||||||||

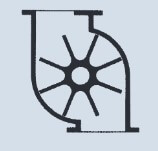

ROTARY GATE VALVES HGV

| Type | Inlet/Outlet [mm] | Throughput rate [m3/h] | Feed size [mm] | Installed Power* [kW] | Weight [kg] |

|---|---|---|---|---|---|

| HGV 45 | 185 x 500 | 40 | 40 | 1.5 | 463 |

| HGV 48 | 185 x 800 | 65 | 40 | 1.5 | 540 |

| HGV 410 | 185 x 1,000 | 80 | 40 | 1.5 | 601 |

| HGV 56 | 220 x 600 | 75 | 50 | 2.2 | 651 |

| HGV 58 | 220 x 800 | 100 | 50 | 2.2 | 740 |

| HGV 510 | 220 x 1,000 | 125 | 50 | 3 | 850 |

| HGV 66 | 290 x 600 | 110 | 60 | 2.2 | 1,018 |

| HGV 68 | 290 x 800 | 150 | 60 | 3 | 1,135 |

| HGV 610 | 290 x 1,000 | 190 | 60 | 3 | 1,358 |

| HGV 86 | 359 x 620 | 200 | 80 | 3.7 | 1,401 |

| HGV 88 | 395 x 820 | 265 | 80 | 3.7 | 1,629 |

| HGV 810 | 395 x 1,020 | 330 | 80 | 5.5 | 1,825 |

PRODUCT DESCRIPTION

The perfect introduction to your process.

These valves are used to transfer flowing material from one process stage to another. Depending on the particular requirement, they can be used as either feed or discharge valves, or as air locks to seal off a part of the process.

HAZEMAG gate valves are highly reliable, extremely robust, and easy to maintain.

HAZEMAG has supplied hundreds of gate valves worldwide. Each individual application is carefully considered to determine the most suitable type and design of valve, and we place great emphasis on the quality of our gate valves; a feature highly valued by all our customers.

Range of Application

Feed and discharge valves for processing equipment such as dryers, kilns, electrostatic precipitators, bag filters, cyclones, classifiers, hammer mills, ball mills, vertical roller mills, etc.

Material Characteristics

Granular, fine, coarse, lumpy, etc.

Pendulum Flap Gates: up to approx. 550m3/h (depending on model)

Rotary Gate Valves: up to approx. 550m3/h (depending on model)

Examples of materials handled:

Activated Charcoal, Aluminium Hydroxide, Aluminium Grits, Aluminium Hydrate, Anhydrite, Anode Scrap, Ash, Bentonite, Blast Furnace Slag, Calcium Chloride, Cement, Chalk, Chemical Gypsum, Chrome Hydroxide Filter Cake, Chrome Ore, Clay, Clinker, Coal, Coke, Copper Cement, Copper Concentrate, Dolomite, Electrode Coke, Feldspar, Filter Cake, Flue Gas Gypsum, Fluorite, Graphite, Green Coke, Gypsum, Iron Ore, Kaolin, Limestone, Magnesite, Marl, Petroleum Coke, Phosphate Rock, Pozzuolana, Raw Meal, Raw Meal Grits, Slag Sand, Splint Coal, Trass, Titanium Dioxide.

Pendulum Flap Gates: up to approx. 500mm (depending on model)

Rotary Gate Valves: up to approx. 80mm (depending on model)

Rotary Gate Valves with Retracting Shield: single lumps up to approx. 300mm (depending on model)

- For high temperature applications

- Fabrication using special materials

- Central lubrication

- Measures to prevent material caking and to reduce wear, etc.

Mainly used as feed or discharge valves for coarse, lumpy material.

Special feature

Inlet and outlet are offset at a tangent to the rotary gate, resulting in much reduced housing wear, and practically no danger of material jamming caused by large lumps.

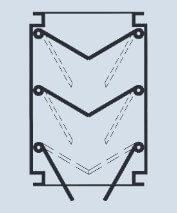

Mainly used as feed or discharge valves for coarse, lumpy material at high capacities and high differential pressures.

Special feature

- Ability to handle coarse material containing lumps up to 300mm (depending on model)

- DPS

- ZS