Key Features

HORIZONTAL IMPACT CRUSHER HHI

TECHNICAL DATA

PRIMARY HORIZONTAL IMPACT CRUSHER HHI

| Model | Max. Feed Size [mm] | Capacity [t/h] | Power Requirements [kW] |

|---|---|---|---|

| HHI 1515 | 1.000 x 1.400 | 500 - 1.800 | 160 - 500 |

| HHI 1518 | 1.100 x 1.750 | 800 - 2.500 | 315 - 630 |

| HHI 1521 | 1.100 x 2.100 | 1.000 - 3.000 | 500 - 630 |

| HHI 1525 | 1.100 x 2.400 | 1.200 - 4.000 | 630 - 750 |

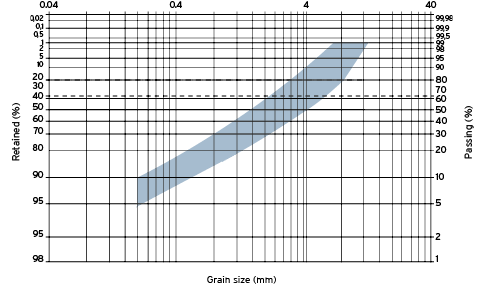

Granulation Curves

PRODUCT DESCRIPTION

The HAZEMAG HHI Horizontal Impact Crusher comprises two machine components: the crushing roll and the chain conveyor. The arrangement of the crushing roll above the horizontal chain conveyor permits the conveyor to be utilised as both feed conveyor and discharge conveyor. This system for crushing has achieved proven success in numerous applications such as coal and ore mining, both above and below ground, in natural stone processing, and for the recycling of concrete and construction rubble.

This mode of operation of conveying the feed material via the ‘at-grade’ chain conveyor, to a rotating impact roll, crushing it and discharging directly onto the conveyor again, is particularly suited to large-scale crushing operations.

Crushing material in the horizontal flow, without a directional change, is the basic operating principle of the HAZEMAG HHI and results in an extremely compact design, with very high throughput rates. The impact roll crusher is equipped with PLC control which monitors power consumption of both the impact roll and the chain conveyor. This control automatically protects the plant against blockages and overload; allowing fully-automated operation of the plant. Final product specification can be influenced by adjusting the height and speed of the crushing roll, as well as varying the conveyor speed.

The HAZEMAG HHI series is a modular system designed to fulfil many different tasks in the mining and bulk goods industry. The machine’s equipment, with the focus on its options, allows for a selective adaptation to the operators’ specific requirements.

Particular advantages of the HAZEMAG HHI series include:

- At-grade material feeding

- Conveyor-compatible crushing directly in the working area

- Crushing is possible in tunnel situations

- Assembly does not require construction of foundations

Further possible equipment variations:

- Feeding bin

- HAZEMAG Roller Screen HRS integrated in chain conveyor

- Variable length of chain conveyor

The following mobility options are possible:

- Steel substructure with skids

- Powerless crawler track assembly

- Powered crawler track assembly