Our Horizontal Crushers

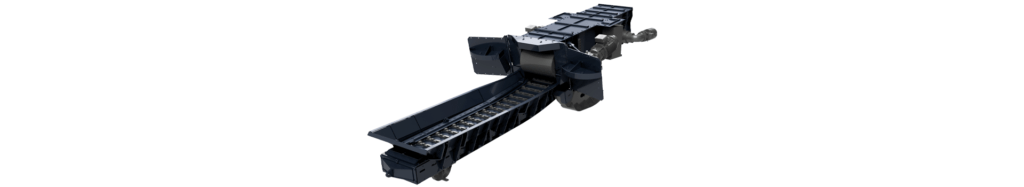

Feeder Breakers as well as Horizontal Impact Roll Crushers are – by the end of the day – not just crushers; they are already crushing plants, which work according to the field-proven principle of crushing in the horizontal material flow.

The Chain Feeder transports the material into the crushing chamber. The rotating crushing roll is equipped with crushing tools (picks) and the material is crushed by impact force on the Chain Feeder. Feeding the HAZEMAG Feeder Breaker may happen via loaders, excavators or heavy trucks directly onto the chain conveyor. In operation mode, the material is being hauled by the fly bars beneath the crusher roll, whereby the material directly in front of the crusher roll is being cut by the picks. Those picks lead the chips in direction of the chain conveyor, which hauls them to the transfer point. The fines of the feed are falling between the bars and are not being stressed by the crusher roll. Therefore, the amount of the fines is only increased by direct crushing. Subsequently, the broken material is being transported via belt conveyors to further processing equipment or is being stockpiled.

The product size is decisively determined by the design and the arrangement both of the picks on the crushing roll as well as of the scrapers within the conveyor. By means of the height-adjustable crushing roll and the adjustment of the chain conveyor’s conveying speed, e. g. via a frequency converter, the granulation size may be adjusted to customer requirements variably on the fly. Therefore, HAZEMAG Feeder Breakers are mainly used as primary crushers close to the face for producing material, which is capable being transported by belt conveyors and is suitable for further processing. Normally, the size of Feeder Breaker feed material is about 1,000 mm and the D95 product size is above 80 mm. Fields of application and limits of application: Due to its design HAZEMAG Feeder Breakers are being used in aboveground operations and underground operations equally. The HAZEMAG HFB system is a modularly designed system, which fulfills a multitude of tasks in mining, on stockyards and trans-shipment sites and in the bulk goods industry. By means of different equipment versions the plant may be modularly adapted to the operators’ respective requirements and wishes. Basically, the feed material needs to be brittle, reasonably dry, mainly not sticky and can be ductile to some degree. However, some special measurements are optional, amongst other scrapers and drag chains. Usually HAZEMAG Feeder Breakers are used for the comminution of

- Potash and rock salt

- Gypsum and chalk

- Coal

- Slags

- Petroleum coke

The machine size and the design are basically determined by the throughput and by the max grain size. The crushed material needs to be pulled through between the crusher roll and the fly bars or the base plate of the chain conveyor. Therefore, basic parameters are the width of the rotor and the crushing chamber, the diameter of the rotor and the width of the chain conveyor.

A HAZEMAG Horizontal Impact Roll Crusher mainly consists of the same main components as the Feeder Breaker.

Apart from the fact that the cross section of the Chain Feeder installed in a Horizontal Impact Roll Crusher is of a different design, the description is similar to the Chain Feeder installed in the Feeder Breaker.

The Crushing Roll of the Horizontal Impact Roll Crusher is equipped with impact elements. These elements can be re-adjusted with the wear and offer a utilization degree of some 70%. Apart from that, the description of the Crushing Roll of the Feeder Breaker remains.