Materials recovery with recycling plants

…recycling plants today for a better tomorrow.

Since 1946, HAZEMAG has been a pioneer in the recycling industry and is, today, a global leader in custom-made solutions for crushing and recycling materials.

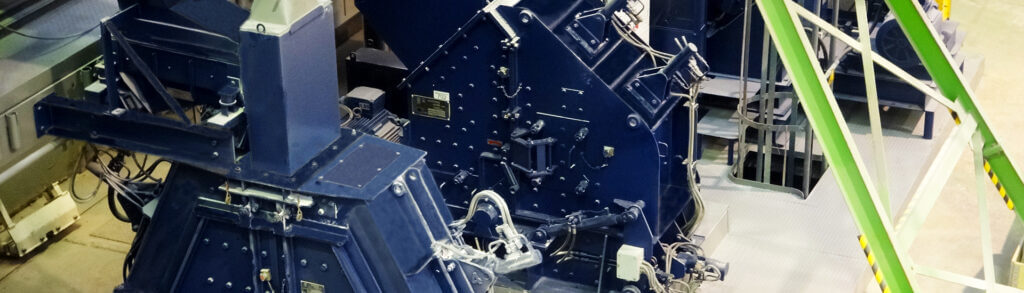

HAZEMAG’s involvement in the recycling industry began with the “Andreas Impact Crusher”… the very first Impact Crusher of its kind, developed in post-war Germany for processing rubble and producing aggregate products to be used for rebuilding. Today, with its immense process know-how, and high quality, innovative machines and plant design, HAZEMAG remains a global leader in providing proven, efficient, custom-made solutions for the crushing and recycling of materials, offering customers the highest availability and lowest downtime.

Today, HAZEMAG’s dedicated recycling team plays a significant part in the company’s contribution to a global vision; giving life to previously used but valuable resources, and making a positive impact on the reduction of waste materials such as plastics, for the benefit of our planet and its inhabitants.

With its process know-how, high quality, innovative machines and recycling plants, HAZEMAG remains a global leader providing proven and custom-made solutions in the crushing and recycling of materials such as rubble, concrete, asphalt, glass, and much more.

Recycling equipment in our test centre allows HAZEMAG engineers to test customers’ products, and determine the optimum solution for their recycling plant and for the recovery of specific materials.

Perhaps more typically than in many other industries, success in the recycling sector is often determined by the quality of the control and management of the raw materials, to ensure the recycling facility operates as efficiently as possible, with minimal resultant waste.

To achieve this, a high-tech processing system must offer a very high level of flexibility, extreme resilience, and the ability to adapt to a wide range of variation in the raw materials.

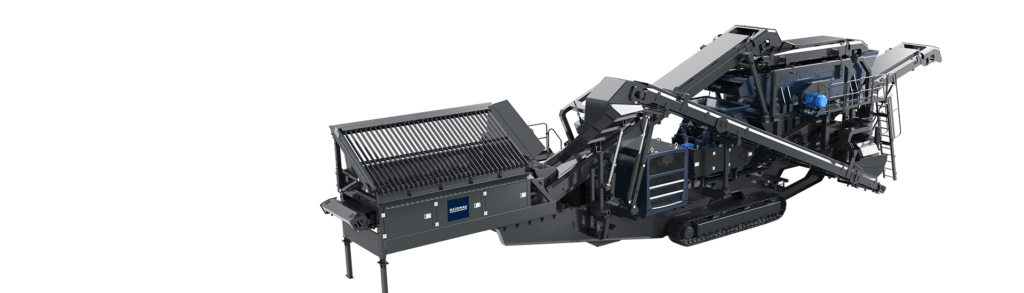

The decision to operate a fixed/stationary plant, versus a mobile recycling plant, is generally influenced by the availability of raw materials, the projected production rates, and local demand for the recycled products.

Typical quality control, raw material management, and processing methods will include:

- Selective demolition of buildings

- Inspection and monitoring of the incoming material

- Raw material identification, classifying and selective sorting

- Raw material stockpiling according to its make-up / mixture

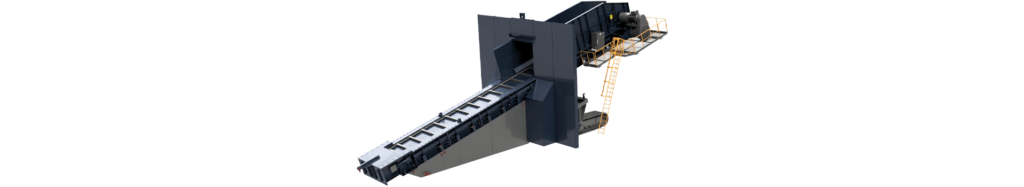

- Material preparation: pre-sizing, sorting and removal of larger tramp metal

- Metal identification, preparation and possible removal

- Sorting out of non-mineral fractions

- Separation of light materials

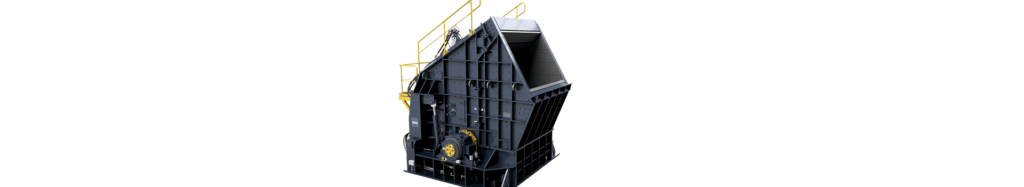

The design of recycling plants is determined by the composition and characteristics of the feed material. The flexibility of recycling plants, and configuration of the component parts, must be such that they are capable of processing a wide range of raw feed material; from clean building rubble to mixed building rubble, as well as large concrete products – all of which can potentially contain large amounts of tramp metal.

The level of technology and automation needed in the recycling plant design also depends on the requirements for the finished product; factors such as product size and shape requirements, material composition and, perhaps most importantly, the level of precision and purity required.

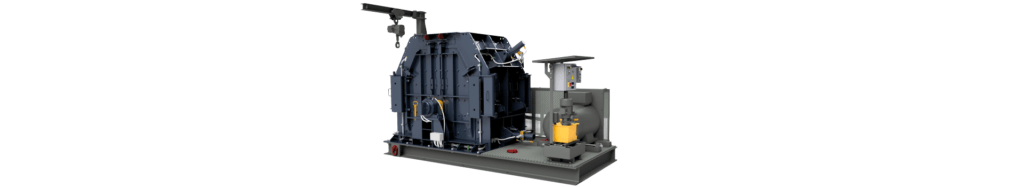

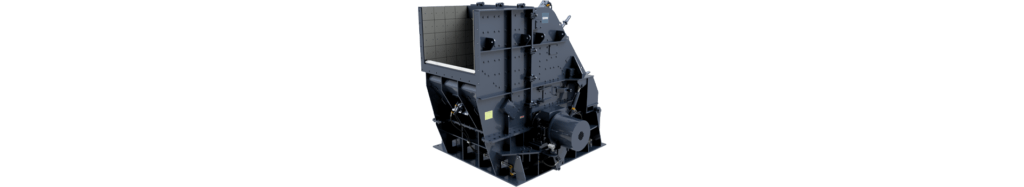

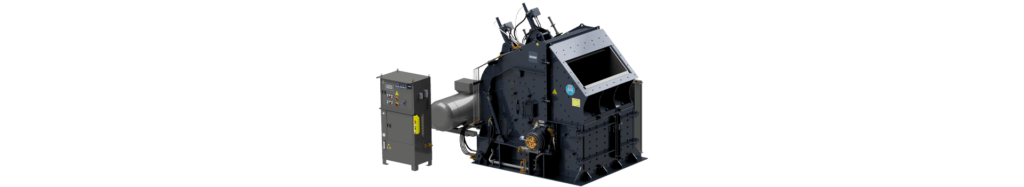

Although the overall design and selection of ancillary equipment can vary, the key component, and the heart of any recycling plant, is its crushing unit… and appropriate crusher selection will directly affect the success and profitability of any recycling operation.

HAZEMAG is well-known for its proven technology and machinery for processing building rubble, and this expertise and know-how is being used to reduce the recycling industry’s wastage of other usable materials.

The successful processing of a wide range of demolition and construction debris into an acceptable, saleable product is the target for recycling plants. This is particularly relevant in the business of rubble processing, where crushing and screening plants are commonly employed. With material recovery facilities, optimised equipment can reduce the waste of valuable materials such as minerals, metals and more.

RECYCLING PRODUCTS

- All

- dynarox

- Impactors

- Horizontal Crushers

- Feeders

- Automation

- Material Testing