Our Sizers

These machines were developed to crush material where height is an issue: Underground! The first applications focused on primary crushing of coal underground.

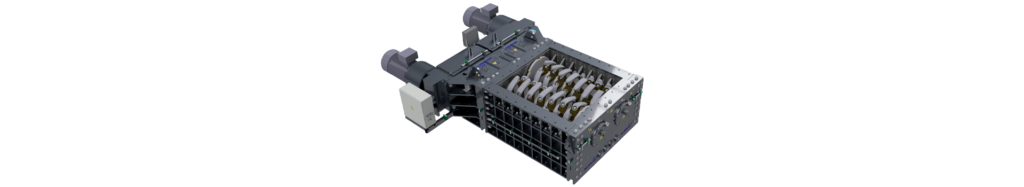

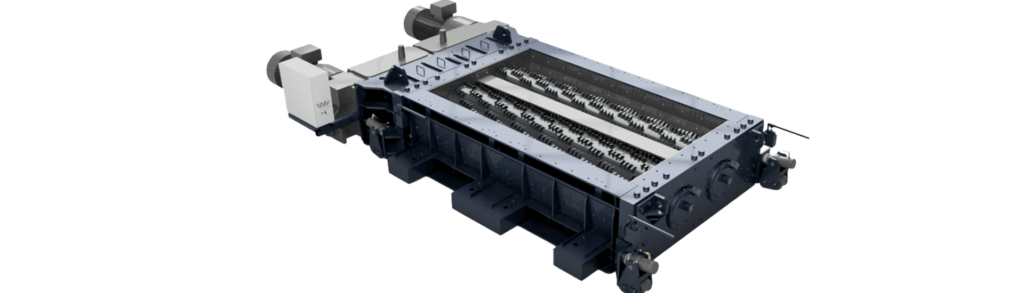

At the first look it appears as if the method of operation of a Center Sizer would be identical to a Double Roll Crusher. It is in fact very close, however, not identical. Still today, customers are not using always the correct terms because of this irritation. By the end of the day, we, as experts, would have to make the decision on which crusher would be the best choice. The operating principle is based on a continuous generation of pressure between two counter – rotating rolls, so that crushing takes place without interruptions in contrast to the intermittent Jaw Crushers. Due to the small number of high teeth big lumps can immerse deep between the rolls and are crushed immediately. The force acting on material is punctual and even not plane as it is typical for Jaw Crushers. The result is a minimization of fine generation. In contrast to a Double Roll Crusher, the basic concept of the Mineral Sizer is the use of two rolls with smaller diameter shafts, because of the operation at a lower rotational speed by a direct high torque drive system. This design produces three major principles which all interact when breaking materials using sizer technology. The unique principles are the three-stage breaking action, the rotating screen effect, and the deep scroll tooth pattern.

The three-stage breaking action: Initially, the material is gripped by the leading faces of opposed roll teeth. These subject the rock to multiple point loading, inducing stress into the material to exploit any natural weak nesses. At the second stage, material is broken in tension by being subjected to a three-point loading, applied between the rear tooth faces, respectively shafts of the rolls. Any lumps of material that remains oversize, are broken as the rolls chop through the fixed teeth of the breaker bar (primary sizers only), thereby achieving a three-dimensional controlled product size. The rotating screen effect: The interlaced toothed roll design allows free flowing undersize material to pass through the gaps. The deep scroll tooth pattern: The deep scroll conveys the larger material to one end of the machine and helps to spread the feed across the full length of the rolls. This feature can also be used to reject oversize material from the machine. This effect is only used in special applications. Fines are minimized because already small enough materials pass freely through the crusher with almost no further size reduction.

Similar to a Double Roll Crusher, the coefficient of friction between the roll surface and the material to be crushed, incorporated with a relation between the size of the feed and the size of the product fixes the diameter of the rolls and also determines whether a particle will be drawn into the rolls and gets crushed or not. The volumetric capacity together with a filling factor between the toothed gaps determines the width of a Sizer. Crushing ratios can go up to 7:1, depending on the compressive strength of the feed material. Center Sizers are typically used in applications in which fines are to be minimized. They are employed for crushing of oil seeds, coal, phosphate rocks, abrasive materials, lime, limestone, clay, gypsum, marl, chalk, salts, Petroleum coke and others. They are also applicable for adhesive feed material. In secondary sizer applications, HAZEMAG can also offer a side ejection for hard and large material. The arrangement of the teeth is that, that material, which is both, too hard and too large, is transported to the non-drive side of the sizer and ejected. Please note that only lumps which show a significant difference in compression strength and size at the same time will be ejected.

Even though, HAZEMAG Center Sizers are available for primary or secondary applications, we do not show this in different models or types. The difference is made by the type of used rolls, with or without breaker bar. However, as a rule of thumb it could be said that a primary center sizer starts at a diameter of 1,000 mm, whereas secondary center sizers end at that diameter.

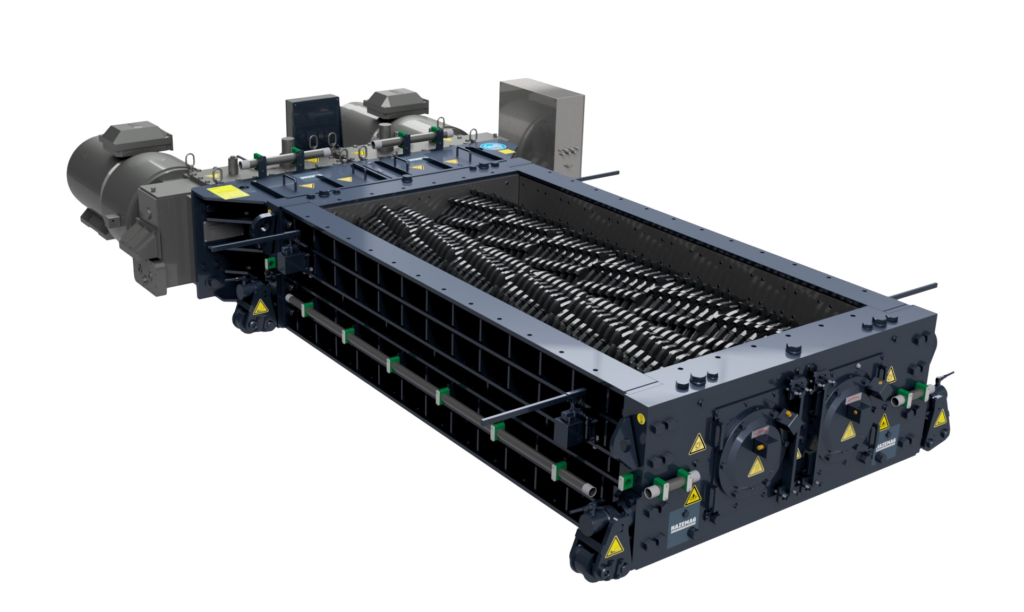

HAZEMAG Side Sizers are ideally suited to the smooth crushing of soft- to medium-hard materials with a low percentage of fines in the product.

The operating principle is based on a continuous generation of pressure between the crushing roll and side wall, so that crushing takes place without interruptions in contrast to the intermittent Jaw Crushers. Due to the small number of teeth, big lumps can immerse deep between the roll and wall and are crushed immediately. The force acting on material is punctual and even not plane as it is typical for Jaw Crushers. The result is a minimization of fine generation.