Our Feeders

Feeders are required for the uniform and continuous feeding of crushing and sizing machines. HAZEMAG Push Feeders are very rugged hopper discharge units, which can also be supplied with infinitely variable mechanical or hydraulic drives. HAZEMAG Chain Conveyors are used mainly for hopper extraction of lighter materials and as spillage conveyors underneath apron feeder

The HAZEMAG rapid dryer, also known as centrifugal shaft dryer in the literature, is a proven dryer design in practice and combines the advantages of convection drying and DC drying, whereby a high efficiency is achieved. Due to the mechanical turbulence of the dry material with throwing blades and simultaneous flow through with hot gas, thermally gentle drying is possible in a short time. Gas or light oil burners are usually used to heat the drying air for applications in the mineral industry. The combustion gases are mixed with a proportion of ambient air to average drying air temperatures between 800°C and 900°C.

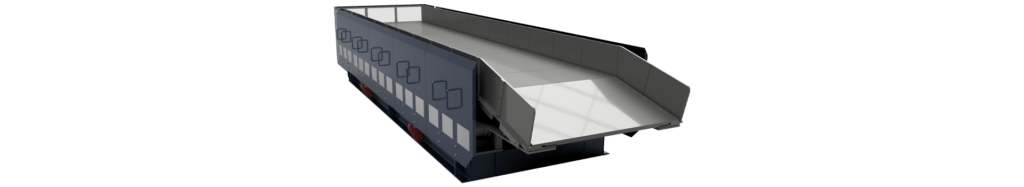

Apron conveyors are the most widely used extraction devices and operate in stationary as well as mobile plants. They are usually installed at an angle of 20 – 23 degrees. This arrangement minimizes the installation height of the crushing plant. The width and length of the conveyor are determined by the specific requirements, the downstream equipment, and the conditions prevailing. Compared with push feeders, these machines have more moving parts and are thus correspondingly more expensive. The apron conveyor consists essentially of the support structure, the drive and take-up stations, the traction elements with pans and the actual drive. The support structure is a rugged, torsion-free, welded steel plate design with main and crossbeams, on which the conveying mechanism with drive and take-up stations is mounted. Above a certain width, plastic or steel longitudinal slide rails are provided in case of pan deformation to act as additional supports, in particular in the vicinity of the feed hopper.

Apron conveyor aprons are of welded steel plate design, with reinforcing ribs on the undersides. Flights are welded onto the top faces. There are unavoidable gaps between the individual pans, especially at the take-up station; in order to prevent material from trickling through these gaps, special seals are fitted. To prevent material escaping at the sides, the pans are fitted with overlapping side plates or else the distance between material guide and outer edge is adequately sized. Moreover, the gap between conveyor pans and material guide must be as small as possible. Often, a scraper chain conveyor is installed underneath the apron conveyor to intercept spillage material.

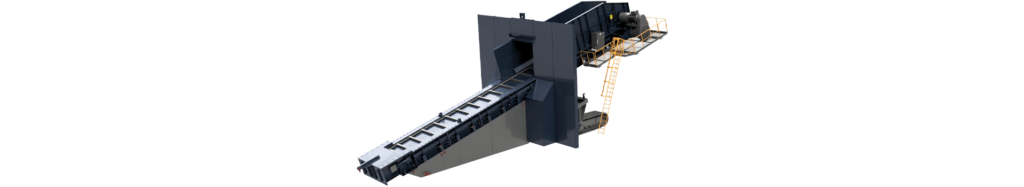

Chain conveyor Chain conveyors and scraper chain conveyors are used as extraction devices from feed hoppers for the conveyance of non-abrasive materials. Two or more strands of round-link chain are connected by flights, which transport the material in the upper stringer on the wear liner-covered conveying surface. The spillage material is collected in the lower stringer and returned to the conveying surface via the take-up station. The drive station consists of the drive shaft with sprockets and the actual drive, which is usually a tapered spur gear drive with squirrel cage motor or hydraulic motor. Speed control is affected by electric motor via frequency converter. The take-up station also comprises a shaft and chain drums. The chains are tensioned and aligned by means of take-up spindles. The freestanding supporting framework is of rugged welded steel design, to which the necessary guide skirts can be fitted.