Application

Especially designed for the effective drifting of tunnels and galleries with small cross sections of 9 m2 to 22 m2 the HRE combines the advantages of

- A road heading machine

- A flexible drilling jumbo

- An effective excavator

All components have already been successfully used in mining or tunneling under tough conditions.

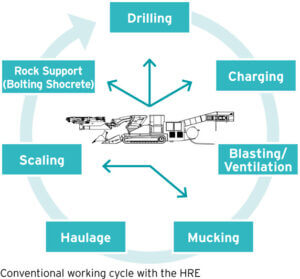

Blast hole drilling as well as charging, loading, scaling and rock support are possible with only one machine.

Thus any passing situations in tunneling are completely avoided.

Description

Quick loading, minimal space requirement as well as an optimized switching from mucking to drilling operation clearly distinguish the HRE from conventional systems.

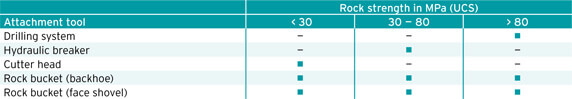

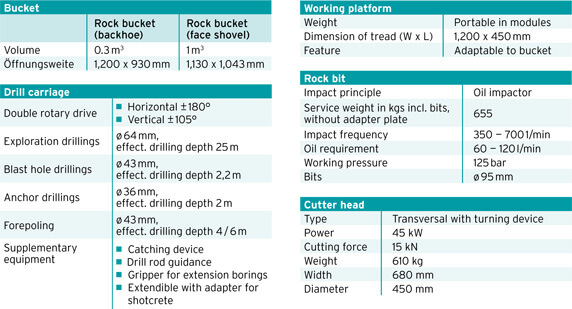

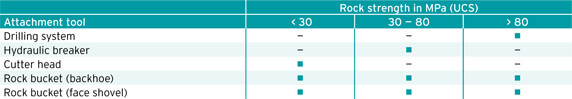

It is the innovative boom which especially determines the performance. It is fitted with a vertically as well as horizontally working parallel holding kinematic system. Besides the bucket and the drilling unit nearly all attachment devices such as hydraulic breaker and cutter heads may be installed via a hydraulic quick-change unit.

- Applicable in small cross sections from 3.3 x 3.3 m

- Electro-hydraulically driven

- Liftable and lowerable loading table

- Active loading support by means of hydraulically driven gathering arms

- Transfer segment of conveyor may be independently lifted and lowered

- Guiding device, e.g. for drilling system

- Multi-functional boom with horizontal and vertical parallel holding technique

- Remote control

- Direct loading in longitudinal axis of the tunnel

- Hand-operated hydraulic breaker in the front area

- Hand-operated impact wrench for being applied in the front and rear area

- Hydraulic quick-changing unit for an efficient tool changing

- Power input of conveyor motor

- Power input of percussion drill

- Temperature of hydraulics

- Position and orientation of the machine in the drift

- Position and orientation of the drill carriage for exact heading

- Localisation of the operator in hazard areas

- Data telecommunication

- Maintenance planner