Rotor repair for HAZEMAG, KHD, ThyssenKrupp, TITAN & Co.

High-quality repairs from the inventor of impact mills – for maximum service life, safety and efficiency.

With over 175 years of mechanical engineering experience, digital measurement, in-house production and access to all HAZEMAG original drawings, we are your partner for manufacturer-independent rotor repairs. We analyse, repair or manufacture new ones – with documented quality and minimum downtime.

We also deliver reliable results for old machines, third-party products and customised solutions.

Rotor defective? We will get your system back up and running – quickly, precisely and across all manufacturers.

- For all common third-party makes: Repair or new production of HAZEMAG rotors for machines from KHD, ThyssenKrupp, e.g. TITAN and MAMMUT, Pralltec and many more.

- High-quality steel constructions: High-quality rotor segments from our own production – also for old machines.

- Dynamic balancing: Each rotor is checked for imbalance and smooth running and balanced – for optimum performance.

- Maximum precision: Digital measurement, non-destructive testing and detailed documentation included on request.

- Hard overlay welding: On request, we can significantly increase the wear resistance of your rotors through hard overlay welding.

- Security of supply: Long-term availability of spare parts through archiving and digital twin.

The process – from analysis to return delivery

1. Initial consultation & quote

In the first step, a phone call or a short message with a few photos or technical drawings is often sufficient. Alternatively, the defective component can also be delivered directly to us or inspected at your premises.

Our experts analyse the condition and determine the repair options. On this basis, we prepare a transparent, binding quote – with no hidden costs.

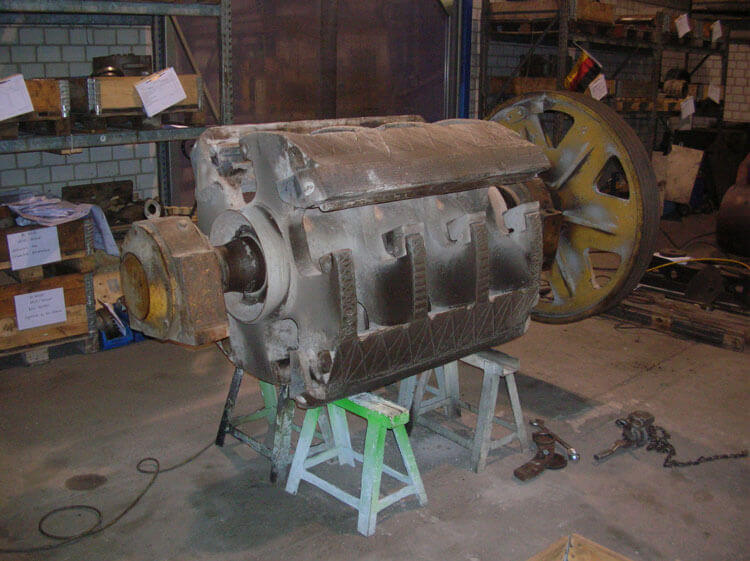

2. Collection & analysis

If you wish, our service team will take care of all the logistics. Depending on the location and condition of the rotor, we offer two options:

- The rotor is dismantled, documented and reconditioned on site.

- Or we organise transport to our factory, where a detailed analysis including measurement and material testing is carried out.

3. Repair / New production

Our repairs are carried out using methods that are true to the original and comply with the manufacturer’s specifications. We use high-quality materials, modern processing methods and over 175 years of mechanical engineering expertise.

If a repair is not technically or economically feasible, we can manufacture a custom-fit new rotor on request, including dynamic balancing and optional hardfacing.

4. Quality control & return shipping

Once the work is complete, we subject each rotor to rigorous quality control. On request, testing and balancing can be carried out directly at your premises or at our factory. You will receive detailed documentation including a test report. Optionally, our experts can supervise the installation or carry it out completely.

Our flyer provides further information

on the repair process with HAZEMAG.

Rotor repair with HAZEMAG – trust through experience

+5,000 rotors

repaired

All

manufacturers

Mechanical engineering

expertise since 1842

Repair with HAZEMAG: Frequently asked questions (FAQ)

All common manufacturers: KHD, ThyssenKrupp, Pralltec, HAZEMAG old machines

Depending on the damage. Initial assessment free of charge, binding quote after inspection.

>20 days storage: one-off fee of €200, monthly fee of €75.

In the event of structural damage or missing data. We will advise you honestly.

Standard: 6-8 weeks. Express on request. For some models: Rental rotors available.

Höhere Standzeiten bei abrasiven Materialien – individuell auswählbar.

Repair your plant with HAZEMAG

Ready to take the efficiency of your machines to a new level? Our experts are on hand to help you develop the best repair solution for your individual requirements. Benefit from durable rotors, lower maintenance costs and smooth production processes.

Oliver Riddermann

Teamlead Repairs

T: +49 2594 77 287

F: +49 2594 77 401

M: +49 176 105 634 20

E: olive1762375683r.rid1762375683derma1762375683nn@ha1762375683zemag1762375683.de1762375683

Markus Graute

Head of Spare Parts Sales

T: +49 2594/77 414

F: +49 2594 77 401

M: +49 152 243 975 93

E: marku1762375683s.gra1762375683ute@h1762375683azema1762375683g.de1762375683